Article by doctors Tom Boujenah and Olivier Boujenah.

KEEP IT SIMPLE WHILE MEETING THE PATIENT’S INDIVIDUAL DEMANDS

Every day in our practices, we are faced with a choice between different treatment options. Experience, scientific literature, and patient preferences all help guide us toward one direction or another.

The case presented below could have been managed using a different approach, but the chosen solution aligned with our philosophy: keep it simple while meeting the patient’s individual demands.

A PATIENT WITH HIGH AESTHETIC DEMANDS

A young patient, in his early twenties, presented for consultation with a purely aesthetic concern. He had been wearing a double-retainer resin-bonded fixed dental prosthesis (Maryland bridge) (Figure 1) for several years, placed due to the congenital absence of the mandibular central incisors. Although the bridge had served him well functionally, the patient now wished to replace it with a more aesthetic solution, better matching the current shade of his natural teeth. After clinical and radiographic assessment, several treatment options were considered, taking into account the patient’s age, bone volume, and aesthetic expectations.

The final decision was to fabricate a new resin-bonded bridge, optimized in terms of both design and shade, using a multilayered zirconia to achieve a natural-looking result.

Fig. 1. Initial situation

Fig. 2. iTero 5D+ optical scan

PRELIMINARY STEPS IN THE DENTAL OFFICE

A pre-treatment impression of the bridge was taken before removal, using the iTero 5D+ scanner (Align Technology; Figure 2). These pre-treatment scans, which are performed almost systematically for our prosthetic reconstructions, allow the laboratory to capture the volume of the existing prosthesis, replicate the previous shape (if suitable), and often visualize wear facets. This helps minimize or even eliminate the need for subsequent adjustments. Then, the existing resin-bonded bridge was removed, and the abutment teeth were prepared as minimally invasive as possible. Once again, the intraoral scanner was used to take an impression of the situation (Figure 3).

Fig. 3. Impression after bridge removal and minimal preparation of the lingual surfaces

PRODUCTION OF THE RESIN-BONDED BRIDGE

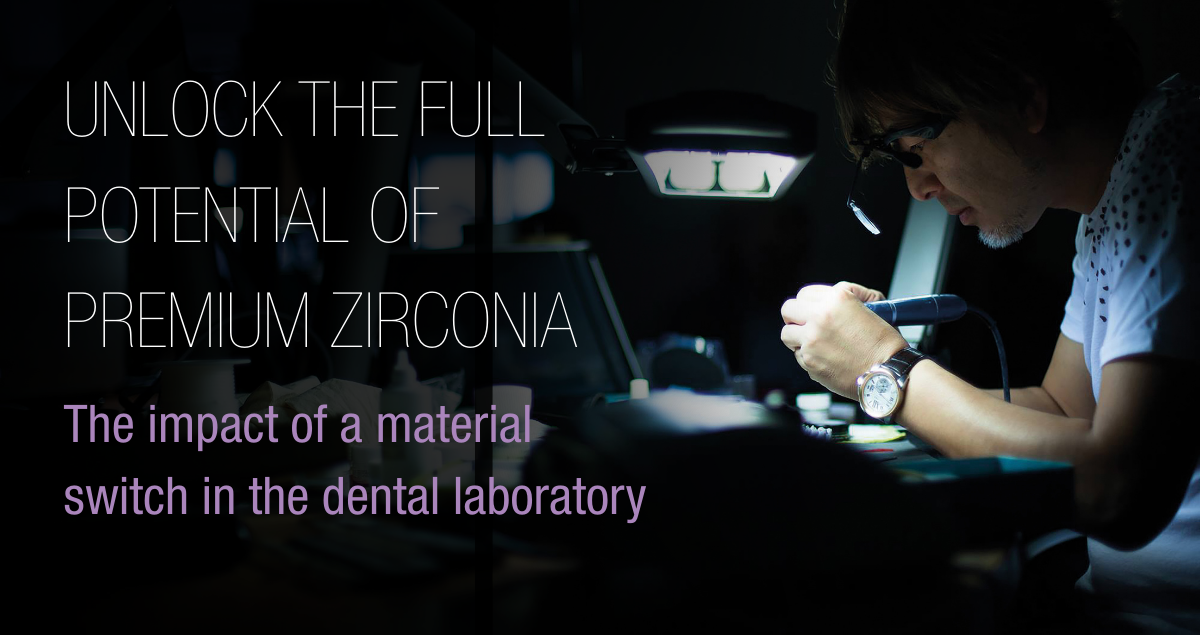

The scan was sent directly from the intraoral scanner to the Design4me platform (a 3D design platform) to carry out the digital design of the planned bridge (Figures 4 and 5). A repositioning key was also designed by the dental technicians to provide for accurate seating of the bridge during cementation (Figure 6). The material of choice was KATANA™ Zirconia YML, a multi-layered zirconia from Kuraray Noritake Dental Inc., shade B1. It seemed most appropriate due to its outstanding physical and aesthetic properties—specifically its gradient in shade translucency and flexural strength (Figure 7).

Fig. 4. Design of the new bridge using exocad software (Design4me platform)

Fig. 5. View of the soft tissue underneath the bridge showing slight gingival compression

Fig. 6. Repositioning key designed using exocad software (Design4me platform)

Fig. 7. KATANA™ Zirconia YML disc (shade shown not representative of the case presented)

The production centre, DIGISMILE, subsequently received the STL files of the bridge and the positioning key, modeled by the dental technicians on the Design4me platform, ready for milling and printing. We also provided the laboratory with intraoral photos to replicate the surface texture, possible characterizations, and shades. The laboratory performed the milling of the bridge using a DWX-52D milling machine (Roland DG). Polishing, surface finishing, and staining were carried out using Komet burs and Miyo liquid porcelain (Jensen). The repositioning key, meanwhile, was 3D printed with a NextDent 5100 3D Printer (3D Systems) using surgical guide resin (Figure 8).

Fig. 8. Milled bridge and 3D-printed key after polishing and staining

DEFINITIVE PLACEMENT IN THE DENTAL OFFICE

The adhesive cementation procedure is one of the most critical steps of the whole workflow. Once the bridge had arrived in the dental office and try-in was successfully completed, the focus was on moisture control and the establishment of ideal bonding conditions. In this context, strict working field isolation with saliva ejectors, cotton rolls, and ideally a rubber dam is essential, followed by the pre-treatment of the abutment teeth and the retainer wings of the zirconia bridge.

PRE-TREATMENT OF THE TOOTH STRUCTURE

Since the tooth preparations are strictly limited to enamel, the following conservative bonding protocol was adopted:

- Etching with phosphoric acid for 30 seconds on the enamel surfaces.

- Thorough rinsing with water, followed by gentle drying without desiccating the enamel.

- Application of PANAVIA™ V5 Tooth Primer (Kuraray Noritake Dental Inc.), followed by thorough drying with mild air after a 20-second waiting time. This primer contains MDP, which is essential for reliable enamel/zirconia adhesion.

PRE-TREATMENT OF THE ZIRCONIA WINGS OF THE BRIDGE

Even though the intaglio surface was sandblasted in the laboratory, it is crucial to repeat this step in the clinic:

- Cleaning with KATANA™ Cleaner (Kuraray Noritake Dental Inc.) for 10 seconds or ultrasonic cleaning for 5 minutes, followed by rinsing with water.

- Sandblasting with 50 μm aluminum oxide (Al2O3) at 2 bar.

- Application of CLEARFIL™ Ceramic Primer Plus (Kuraray Noritake Dental Inc.) to the intaglio surface without rinsing, followed by gentle drying. This primer also contains MDP, providing for a proper chemical bond to zirconia.

ADHESIVE CEMENTATION

With all surfaces pre-treated appropriately, adhesive cementation proceeded as follows:

- Application of PANAVIA™ V5 Paste (universal shade A2) to the intaglio of the bridge.

- Insertion of the bridge using the repositioning key.

- Light curing (“tack” cure) for 3 to 5 seconds to stabilize the restoration.

- Removal of excess resin cement with a dental explorer. Alternatively, excess may be removed immediately with a soft brush before applying to light cure for the margins.

- Final complete light curing according to the manufacturer’s instructions (Figures 9 and 10).

Fig. 9. Clinical situation captured immediately after cementation

Fig. 10. Lateral view of the restoration immediately after cementation

TREATMENT OUTCOME

Thanks to the pre-treatment scan and the overlay of the old bridge with the new one, no adjustments were necessary, although occlusion control remained essential. At a recall after 18 months, gingival integration was satisfactory: The patient was able to use interdental brushes and maintain the prosthesis properly (Figures 11 and 12).

Fig. 11. Clinical situation 18 months after definitive placement

Fig. 12. Lateral view at 18 months

CONCLUSION

In this clinical case, the choice to produce a double retainer resin-bonded bridge, almost identical in design to the previous one, may seem conservative. However, this decision is supported by several factors: The patient’s good tolerance of the previous prosthesis, the tissue integrity of the abutment teeth, and, most importantly, the opportunity to significantly improve aesthetics thanks to advances in materials and bonding techniques, which allowed us to keep preparations minimal and minimally invasive.

This new bridge, designed with highly aesthetic multilayer zirconia and bonded using a strict protocol, achieved a perfectly integrated and natural result without resorting to more invasive options (therapeutic gradient). Furthermore, this approach invites the restorative team to consider emerging trends in resin-bonded bridge design, notably the option of two single-retainer cantilever bridges, which might be considered in similar cases in the future.

This case highlights the importance of individualized treatment planning, which does not rely solely on innovation, but on precise clinical assessment, attentive listening to patient needs and expectations, careful implementation of available tools, and the use of high-quality materials and protocols.

Dentists:

OLIVIER BOUJENAH

Dr. Olivier Boujenah earned his Doctorate in Dental Surgery from Paris V in 1994 and a University Diploma in Maxillofacial Surgical Rehabilitation from Paris VII in 2008. A pioneer in digital dentistry, he founded DIGISMILE, a training center and fully digital laboratory, and DIGISMILE LAB, dedicated to prostheses and surgical guides. He teaches in the Master’s program in Digital Dentistry at the University of Geneva and has pursued advanced training at Harvard University in digital workflows and guided surgery.

TOM BOUJENAH

Dr. Tom Boujenah graduated from the European University of Madrid in 2023 and completed a University Diploma in Oral Implant Rehabilitation at the Pitié-Salpêtrière Hospital in Paris. Based in private practice in the 16th district of Paris, he focuses on aesthetic and functional oral rehabilitation with a particular interest in implant dentistry and digital workflows. Passionate about innovation, he integrates the latest advances in implantology, prosthodontics, and digital dentistry to deliver personalized and long-lasting treatments.