5 Blocks

Il contenuto del sito www.kuraraynoritake.eu/sw_it è riservato agli operatori sanitari e riporta informazioni sui prodotti che possono creare situazioni di pericolo per la salute e la sicurezza del paziente se non correttamente lette, comprese ed applicate da un professionista.

In ottemperanza con quanto previsto dalla normativa vigente, dichiaro quindi, sotto la mia responsabilità, di essere un professionista del settore odontoiatrico e/o odontotecnico e di essere pertanto autorizzato a prendere visione del contenuto presente in questo sito internet

The multi-layered KATANA™ Zirconia Block consists of four layers zirconia in graduated shades allowing the chairside fabrication of natural-tooth colored restorations. Eliminating a time-consuming and complex situation of staining the restoration.

KATANA™ Zirconia Block, the innovative multi-layered zirconia block*1, can be used with Dentsply Sirona's CEREC system*2. Now the 18 minutes sintering program*3 is developed and installed into CEREC SpeedFire. New sintering technology makes it possible to fabricate full zirconia restoration in approx.35 minutes.

*1 CL shade is not a multi layered block.

*2 For using this product, CEREC software 4.5.2 or later is required, and for 18 minutes sintering, software 4.6 or later is required.

*3 In case that wall thickness is less than 3mm using dry milling.

*4 Dry milling is recommended. If wet milling/grinding is performed by using cooling water contaminated by silica-based glass ceramics (lithium disilicate glass, etc.), the translucency of the zirconia may be reduced after baking. Before wet milling/grinding, clean the milling/grinding chamber, cooling water tank and filter insert. The cooling water must be changed in order to assure optimum results.

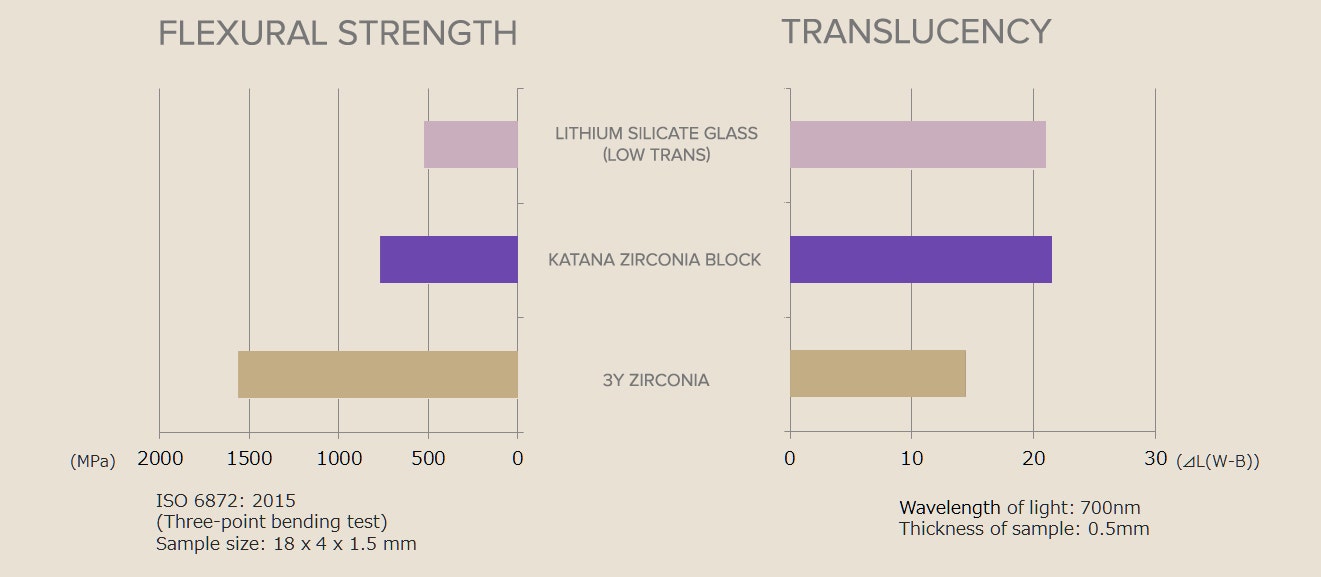

KATANA™ Zirconia Block delivers better mechanical properties than lithium disilicate glass ceramics.

As a result restorations are thinner and more translucent for a more natural-looking, result.

Zirconia is a non-silica-based ceramic which will not respond to a traditional pretreatment method such as, hydrofluoric acid-etching of the internal surface. Micro-mechanical retention achieved through sandblasting and chemical bonding through adhesion (ex. MDP) are key factors for successful zirconia bonding.

PANAVIA™ V5 and PANAVIA™ SA Cement Universal, which both include the MDP adhesive monomer, have high bond strength and durability to zirconia.

Per ordinare, scegliere tra le seguenti opzioni.

5 Blocks

2 Blocks

5 Blocks

2 Blocks

2 pcs.

3 pcs.

5 pcs.

Ecco un elenco di risposte alle domande più frequenti.

What are the main features of KATANA™ Zirconia Block for bridges?

KATANA™ Zirconia Block for bridges allows to mill up to 3 unit bridges to treat the patient on a single visit by using Dentsply Sirona’s CEREC system. These bridges can even be used in the masticatory molar area. Kuraray Noritake Dental's zirconia and multilayer technologies allow the user to fabricate zirconia restorations with natural shade gradation and translucency close to natural teeth.

How many layers does the product consist of?

The product consists of four different colored zirconia. They are arranged in the order of 35% (Body Layer), 15% (Transition Layer 1), 15% (Transition Layer 2), and 35% (Enamel Layer). Please refer to the product catalog for details.

Why is the KATANA™ Zirconia Block offered as STML (Super Translucent Multi-Layered), not UTML (Ultra Translucent Multi-Layered)?

We believe that STML is easier to use at the chairside because it has a well-balanced combination of translucent and mechanical properties.

What is the difference between this product and IPS e.max CAD? What are the advantages and disadvantages of this product over IPS e.max CAD?

This product has a higher mechanical strength (763 MPa) than IPS e.max CAD (519 MPa), which is a lithium disilicate glass*. This product has a multi-layered structure, so it is easier to fabricate a more natural looking restoration than with IPS e.max CAD, a single layer block.

*Data source: Kuraray Noritake Dental Inc. According to ISO 6872: 2015.

What makes it different from other high translucent zirconia blocks?

For restorations with a thickness of less than 6 mm*, our product can achieve high translucency after only 18 minutes** of high-speed sintering.

* CEREC 5.0.2 / inLab 19.0 software versions or newer are necessary.

** In case of dry milling

What are the product’s indications?

KATANA™ Zirconia Block is used for the fabrication of all-ceramic restorations (frameworks, FCZ crowns, FCZ bridges, onlays and veneers).

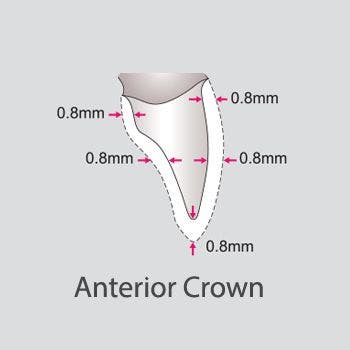

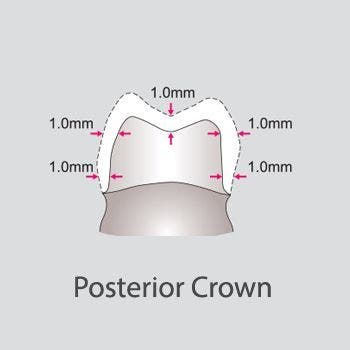

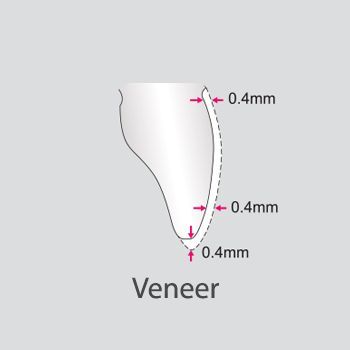

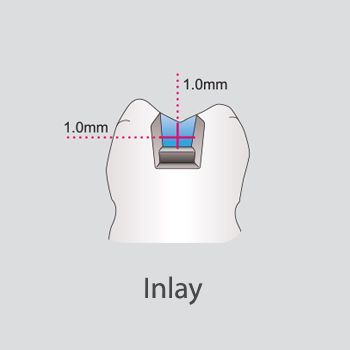

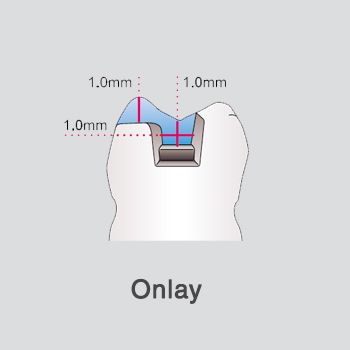

How thick does it have to be?

For this product, you need a minimum wall thickness of 0.8 mm for anterior crown restorations and 1.0 mm for posterior ones.

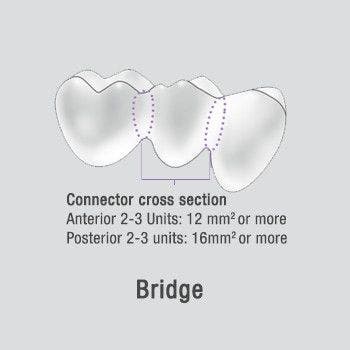

What is the size of the bridge connection part?

12 mm² for anterior bridges and 16 mm² for posterior bridges.

Please refer to the product catalog for details.

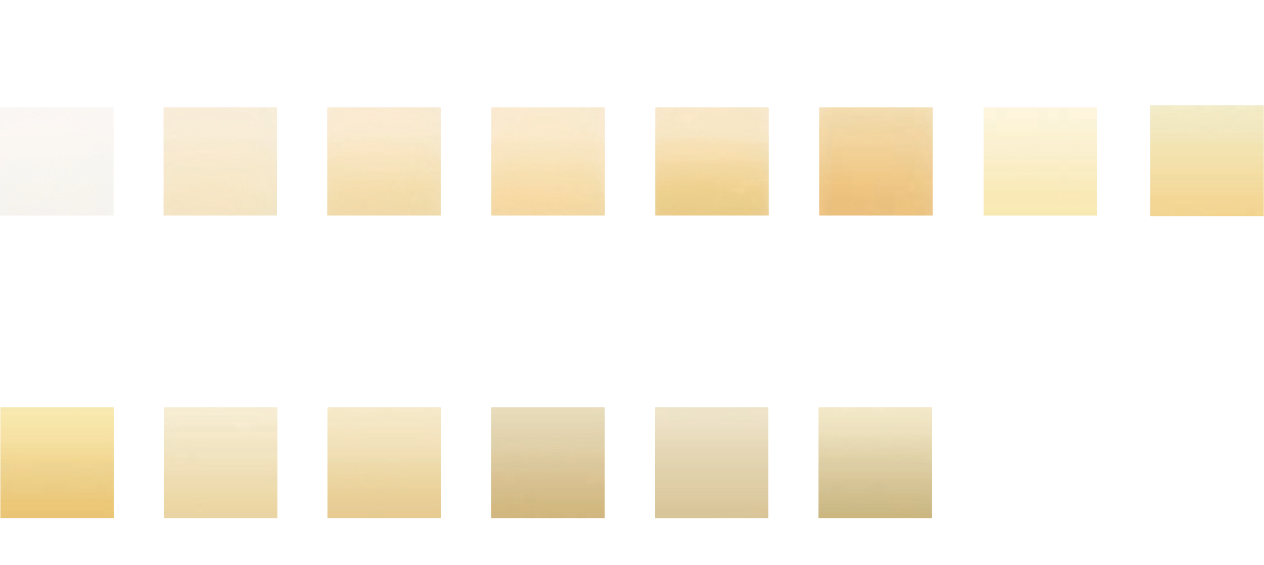

How many shades are there?

14 shades. Please refer to the product catalog for details.

What’s the maximum crown height that can be fabricated?

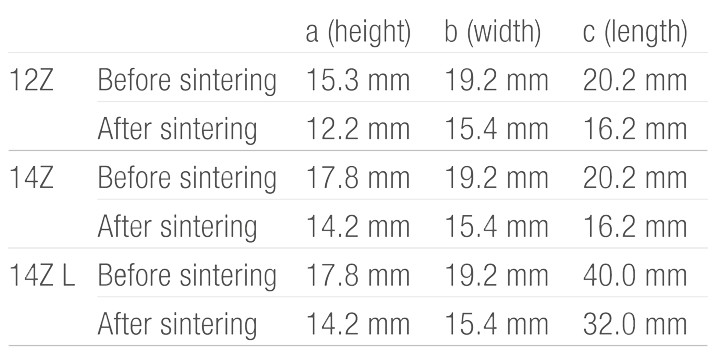

For 12Z, up to 12 mm and for 14Z it’s up to 14 mm. After sintering, the actual size of the restoration will be changed to roughly 80% of each block size referred to in the product catalog. Block sizing may have individual slight differences, but will be adjusted automatically by the software.

What’s the maximum bridge length that can be fabricated?

32 mm with sprue.

Is the 4+ unit bridge included in the indications?

Up to 3 units is indicated. Please do not make 4 + unit bridge even if it can be designed by software.

Is the cantilever bridge included in the indications?

They're not indicated. Please do not make a cantilever bridge, even if it can be designed by software.

How long does it take for each process?

Approximately 5 minutes for intraoral scanning, 10 minutes for design, 15 minutes for milling (45 minutes for 3 unit bridges), 18 minutes (30 minutes for 3 unit bridges) for sintering and 10 minutes for polishing or 20 minutes for glazing.

Is sintered zirconia milled?

Pre-sintered zirconia is milled and then fully sintered afterwards.

Which milling method, wet or dry, is used to mill this product?

We recommend dry milling. It is possible to mill this product using wet milling, but wet milling might achieve a lower level of translucency than expected, if cooling water is contaminated by silicabased glass ceramics (lithium disilicate glass, etc). Besides, when you use wet milling, it takes approx. additional 10 minutes to complete the sintering process, as a drying step is added into the process.

What points should be kept in mind when using wet milling?

If using KATANA™ Zirconia Block with a glass block and resin block in the same machine, it is necessary to wash the milling chamber and filter, and replace the cooling liquid. Insufficient cleaning of the chamber or filter will result in restorations with lower translucency.

Is it possible to mill with Dentsply Sirona’s CEREC inLab?

It can be used with the CEREC inLab software (after version 18.1).

Is it possible to use any other sintering furnace than CEREC SpeedFire?

Yes. A 50-minute sintering schedule is available for all other chairside furnaces, such as the Programat CS4 from Ivoclar Vivadent.

The barcode didn’t work.

If the scanning process failed, please type in the 7-digit number. If there are only 6 digits on the block, please enter a space at the end. Please contact Dentsply Sirona for details.

How many prosthesis can be sintered at a time in CEREC SpeedFire?

Up to 3 crowns or one 3-unit bridge.

Is it possible to use Programat CS4 furnace?

It is possible to use Programat CS4 with 50 minutes sintering. Please refer to the product catalog for details. If you use wet milling, drying process for 10 minutes at 200 degrees is necessary.

How many prosthesis can be sintered at a time in Programat CS4?

Up to 6 crowns or two 3-unit bridges.

Can the competitor’s high translucent zirconia for laboratory-use be sintered in a short time?

It takes longer sintering time to achieve the same level of translucence as our product. Our product is made of zirconia raw materials developed by Kuraray Noritake Dental to achieve high translucency in short time sintering.

Can CERABIEN™ ZR (including CERABIEN™ ZR FC Paste Stain) or CERABIEN™ ZR LF be layered on the restoration?

Yes, it can be layered.

What is the finishing step after sintering?

After occlusal adjustment, finish the restoration by glazing

(with spray or paste) or polishing.

What points should I keep in mind when adjusting restorations after sintering?

Adjust the restoration under running water or wet condition.

What is the glazing process?

After occlusal adjustment, polish the opposing areas using a silicon point containing diamond or a paste containing the same, followed by spray or paste glazing.

What glaze product do you recommend?

We recommend CERABIEN™ ZR FC Paste Stain or Dentsply Sirona's CEREC SpeedGlaze for the CEREC SpeedFire furnace.

Is it possible to use this product with a competitors' spray glaze?

It is possible to use Dentsply Sirona's CEREC SpeedGlaze. We do not have any data about Ivoclar Vivadent's glaze material. Please follow the Instructions for Use of the glaze material.

What is the application time for the glaze?

About 20 to 25 minutes with CERABIEN™ ZR FC Paste Stain (approx. 13 minutes for baking); about 15 to 20 minutes with Dentsply Sirona's CEREC SpeedGlaze (approx. 10 minutes for baking).

What is the polishing process?

After occlusal adjustment, polish the whole restorations with silicon points containing diamond (KATANA™ Twist DIA, etc.), in three steps of the level of polishing, starting from coarse to medium to fine.

Which polishing tool or material do you recommend when finishing the restoration?

We recommend to use a silicon point containing diamond such as KATANA™ Zirconia Twist DIA or a polishing Paste material containing diamond particles, such as Pearl Surface Z (Kuraray Noritake Dental Inc).

What should you keep in mind when polishing?

Please select a shade one level brighter than the targeted shade color, because the restoration will come out a little darker.

Is it possible to perform color adjustment or staining of the restoration after sintering?

It is possible to do this with CERABIEN™ ZR FC Paste Stain.

Can competitors' Stain be used?

Yes. But please use a Stain indicated for zirconia.

Does this product have fluorescence?

The product itself doesn’t have fluorescence, but it is possible to add fluorescence into the restoration with CERABIEN™ ZR FC Paste Stain.

What cement do you recommend for use with this product?

Please use cements that contain MDP, such as PANAVIA™ V5 and PANAVIA™ SA Cement Universal.

How do you treat the internal surface of the restoration?

PANAVIA™ V5: After sandblasting and clean it, apply CLEARFIL™ Ceramic Primer Plus, then dry.

PANAVIA™ SA Cement Universal: No treatment necessary.

How do you treat the tooth surface?

PANAVIA™ V5: Apply PANAVIA™ V5 Tooth Primer and dry.

PANAVIA™ SA Cement Universal: No treatment necessary. We recommend the usage of CLEARFIL™ Universal Bond Quick to enhance bond strength to tooth structure.

Is it possible to cement the restoration temporarily?

Yes, you can.

What kind of equipment do you need to introduce a complete system for using this product?

Among other possible items: AC Omnicam/Primescan, CEREC Milling units (Dry Milling Suction Unit for dry milling), CEREC SpeedFire or other chairside furnace, etc. Please ask Dentsply Sirona for detailed information.

Which versions of CEREC Milling machines can be used for this product?

This product can be used with any version, however we recommend ones with dry milling.

When should the milling bur be replaced with a new one?

It depends on clinical cases, however we recommend that this should be done after about 20 to 25 blocks have been milled.

What is the amount of Yttria?

It is the same as KATANA™ Zirconia STML disc, 3.5 to 5 mol%.

What is the crystal structure?

Approximately 60% is cubic structure and 40% is tetragonal.