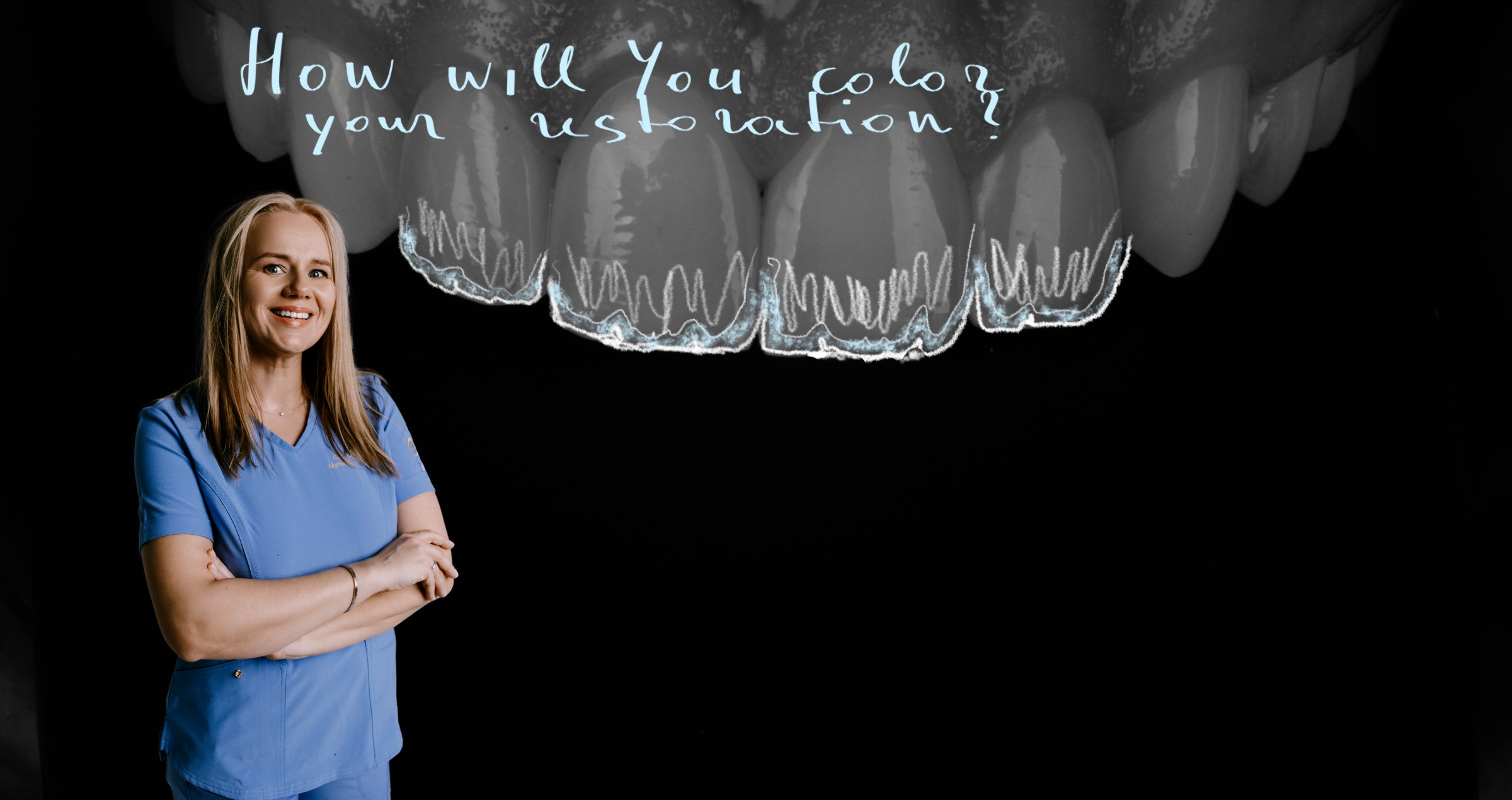

Minimal ceramic layering on a "KATANA™ Zirconia" multi-layered micro-cutback restoration

By MDT Daniele Rondoni.

This clinical report reveals why you should start:

- using fewer ceramic elements

- choosing minimal ceramic layering

- opting for micro-cutback solutions

without missing the quality and value of your restorations.

Advances in materials development and computer-aided processing allow for more streamlined workflows and an improved collaboration between the dental office and laboratory. In order to benefit from the new options, however, it is important that dental technicians embrace their new responsibilities: they need to keep track of the latest changes and need to acquire profound knowledge of how to leverage the materials’ and technologies’ full potential. Being open for new approaches and restoration techniques is part of this game. In return for their efforts, they will be able to achieve unparalleled aesthetic accuracy in a more efficient procedure.

The evolution of dental zirconia is an excellent example for advances in the field of dental materials: many modern zirconia discs have multi-layered structures and natural tranlucencies. Offering top-level performance and high versatility, these variants are increasingly often the materials of choice for the production of high-quality restorations.

The "KATANA™ Zirconia" multi-layered series, for example, is composed of four multi-layered materials: "KATANA™ Zirconia" HTML PLUS with the highest flexural strength (1,150 MPa) and lowest translucency, "KATANA™ Zirconia" STML with medium strength (748 MPa) and a high translucency, and "KATANA™ Zirconia" UTML with a strength above the level of glass ceramics (557 MPa) and ultra-high translucency. The latest add-on in “KATANA™ Zirconia” portfolio is YML - multi-layered zirconia disc that offers both flexural-strength and translucency gradation. With this portfolio, it is possible to select the right material for every specific need (e.g., high-strength variant for multi-unit restorations, high-translucency variant for anterior crowns). Using the zirconia with a monolithic or minimal vestibular cut-back design and a small layer of porcelain enables us to reduce the wall thickness of the restorations (as compared to a traditional framework design and full porcelain layer). As a consequence, a less invasive tooth preparation is required.

In addition, the design meets the functional needs in terms of low abrasiveness and high toughness, while a sophisticated aesthetic outcome is achieved using micro-layering with the materials contained in the 4.4.1. kit. These can be a winning alternative to traditional ceramic multi-layer solutions, as revealed using the following case example that illustrates the use of the 4.1. technique.

Fig. 1. Digital impression.

Fig. 2. Digital impression taken with the temporary in place.

Fig. 3. Digital model of the prepared teeth imported into the CAD software.

Fig. 4. Digital model of the teeth with temporary imported into the CAD software.

Fig. 5. Designing of four zirconia crowns: Transparent view.

Fig. 6. Designing of four vestibular enamel cutback zirconia crowns.

Dentin structure with internal anatomy

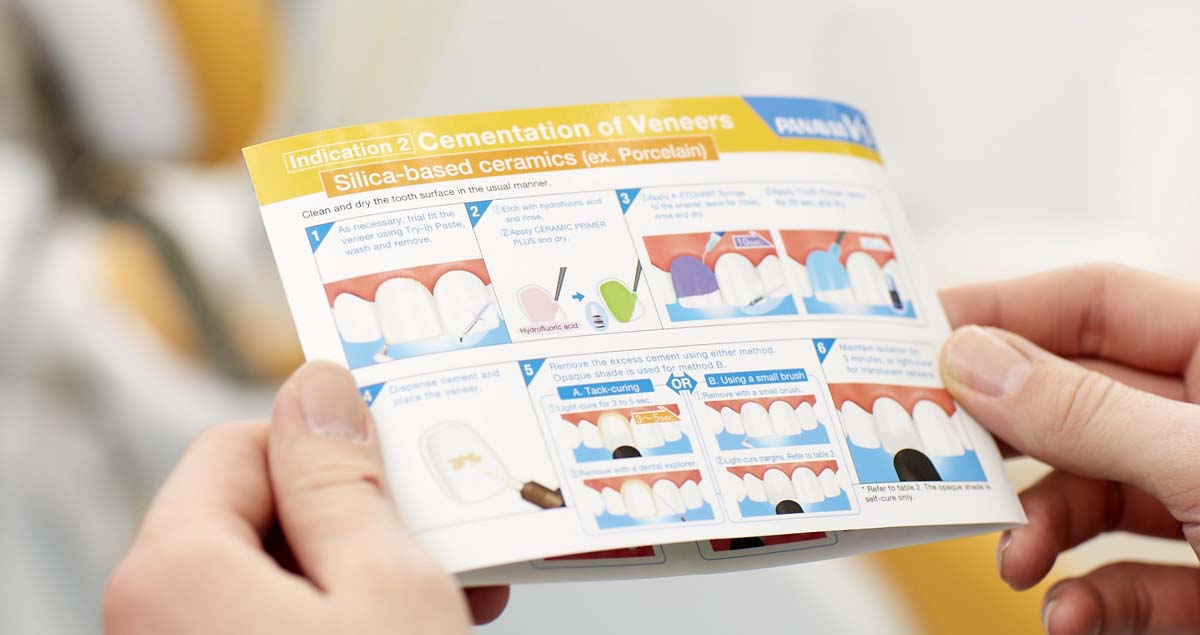

In the present case, "KATANA™ Zirconia" STML, in the shade A2, was selected based on the desired appearance of the final restorations, the colour of the abutment teeth and the space available. The selected design was a minimal vestibular cutback, while the palatal zirconia was left untouched. To replicate the natural aesthetics, we opted for vestibular micro-layering with single luster porcelain and specific internal design of the mamelons.

In order to achieve the best possible aesthetics, it is fundamental to incorporate the internal anatomy into the pre-sintered vestibular surface, and to precisely follow the recommended sintering protocol. Only a flawless sintering procedure will lead to the ideal translucency and correct shade appearance. Following sintering, the surface should be treated with a sandblasting unit (aluminium oxide, particle size 50 μm, pressure 1 to 2 bar).

Fig. 7. Cross-sectional view for a check of the correct thickness.

Fig. 8. Crown made of "KATANA™ Zirconia" STML after sintering.

Fig. 9. Checking the fit of the crowns on the printed working model.

Fig. 10. ILS technique: colour map.

Fig. 11. Application of "CERABIEN™ ZR" Internal Stains.

INTERNAL STAIN ADVANTAGES

- Powder becomes gel and is always ready for use

- The real colours are revealed already before baking

- Optical effects are achieved simply and rapidly

- Excellent adhesion to zirconia is ensured

To improve the mimicry effect, we use the internal light stain technique on the zirconia surface. Incisal Blue one is applied around the mamelons, Mamelon Orange 2 directly on the mamelons for a natural effect. For a calibrated chromaticity, A+ may be added in the cervical area.

Fig. 12. Appearance of the internal stains on the surface after firing.

Fig. 13. Light dynamics after firing.

Fig. 14. Luster layer: Colour map.

Fig. 15. "CERABIEN™ ZR" Luster Porcelain LT1 applied in a micro layer.

Fig. 16. Layering with LT1.

The vestibular body and incisal morphology are completed by adding a single ceramic micro layer of CZR Luster Porcelain LT1.

Before finalizing the restorations, the zirconia surface and texture were optimized with a stone and rubber polishers.

Polishing of the palatal surface was accomplished with Pearl Surface Z diamond paste before a final self-glaze step in the furnace.

Fig. 17. Appearance of the minimal ceramic layer after a single firing procedure.

Fig. 18. Light dynamics after firing.

Fig. 19. Final crowns after mechanical polishing.

Fig. 20. Check on the elements will be carried out on the printed digital model.

Fig. 21. Final situation after cementation.

Fig. 22. Palatal view of the final situation.

Conclusion

Considering aesthetic requirements and case difficulty, today it is possible to adopt different 4.4.1. approaches. In combination with the present generation of multi-layered zirconia, they allow the modern technician to make the best use of digital means to solve complex cases in an easy, effective, and successful manner.

The 4.4.1. system is recommended because it is a selection of materials used in a number of combinations, which help us achieve aesthetically sophisticated outcomes in a feasible, flexible and repeatable way.

For more information about the 4.4.1. system, click here.

Dentist:

DANIELE RONDONI, MDT

- Graduating in 1979, Daniele Rondoni opened a laboratory in 1982, which is also the home of the AAT Community College he founded.

- Teacher and counsellor for the “Italian School for Dental Technicians”at the University of Chieti, University of Sienna and University of Rome Tor Vergata.

- EAED and IAED Active Member and a SICED Associate and O.L.

- International Instructor for Kuraray Noritake Dental products.

- Author of “Tecnica della Multistratificazione in ceramica” (Ceramic Multilayering Technique) and a lab manual about the use of composite materials, introducing his own method – the “Inverted Hardness Layering System”.