Interview with Tomohiro Emoto.

Kuraray Noritake Dental Inc. Launched its first porcelain for porcelain-fused-to-metal restorations – Noritake Super Porcelain AAA*, still available after more than 30 years under the name Noritake Super Porcelain EX-3* – in 1987. The knowledge acquired since then formed the basis for the development of CERABIEN™ ZR and the brand-new CERABIEN™ MiLai portfolio. How much of Noritake Super Porcelain is found in CERABIEN™ MiLai?

*Noritake Super Porcelain AAA and Noritake Super Porcelain EX-3 were designed and launched by Noritake Company Ltd., the predecessor of Kuraray Noritake Dental Inc.

Naturally, the knowledge we have acquired on developing porcelain products has been fully applied in the development of CERABIEN™ MiLai. The methods used to handle Synthetic Feldspar - such as low firing technologies, stable thermal expansion even with multiple baking, particle distribution control – are amongst the most important findings we have acquired since the development of Noritake Super Porcelain AAA. This expertise has been utilized to create both the design concept and development of CERABIEN™ MiLai.

WHAT ARE THE MOST DECISIVE DIFFERENCES FROM OTHERS?

The most decisive difference between CERABIEN™ MiLai and others is that we focus on micro-layering technique with this product. CERABIEN™ MiLai enables you to express life-like colours even with thin layers of porcelain. Also, this is the first porcelain we have launched which is compatible with lithium disilicate as well as zirconia.

Photo: MDT Andreas Chatzimpatzakis

WITH CERABIEN™ ZR BEING AVAILABLE AND CLINICALLY SUCCESSFUL, WHY DID YOU DECIDE TO DEVELOP A NEW LINE OF PORCELAINS AND INTERNAL STAINS?

The best way that we propose to create aesthetic restorations is Porcelain Fused to Zirconia (PFZ) with CERABIEN™ ZR. However, this method requires high levels of expertise and experience which is a lengthy learning curve for beginner dental technicians. As a result, Full Contour Zirconia (FCZ), which does not require such advanced skills and expertise, and which allows virtually anyone to create (albeit not perfect but nevertheless acceptable) restorations, is becoming increasingly popular. CERABIEN™ MiLai sits in the middle of these two methods. It enables technicians to create more aesthetic restorations with a simple, single micro-layering technique, making it ideal for those who wish to produce aesthetic restorations but without the high learning-curve associated with the traditional method, or those who use lithium disilicate materials.

CERABIEN™ MiLai enables you to express life-like colours even with thin layers of porcelain.

IS CERABIEN™ MILAI THE ANSWER TO THE NEW GENERATION OF MILLABLE CERAMIC MATERIALS THAT HAVE IMPROVED A LOT IN TERMS OF MECHANICAL BUT ALSO OPTICAL PROPERTIES IN RECENT YEARS, SUCH AS THE ENTIRE KATANA™ ZIRCONIA LINE-UP, TO OFFER FOR THIS KIND OF MATERIALS A FASTER AND ALSO HIGHLY AESTHETIC FINISHING OPTION?

Yes, it is. Formerly, zirconia materials were mono-coloured and not translucent. However, the improvement of zirconia materials, which began with KATANA™ Zirconia ML followed by KATANA™ Zirconia STML/UTML and KATANA™ Zirconia YML, has been an ongoing process and the aesthetics of the material itself is now very high thanks to improvements in translucency. This has led to the development of CERABIEN™ MiLai, a simple process that can achieve highly aesthetic restorations with thin layers, making the most of the high translucency of the zirconia materials.

WHAT ARE THE SPECIFIC NEEDS OF USERS FAVORING THE MICRO-LAYERING TECHNIQUE WITH RESPECT TO FEATURES OF THE VENEERING PORCELAIN?

When dental zirconia materials were first launched, chipping issues with porcelains for dental zirconia materials were a problem. At that time, dental porcelains were built up on a zirconia framework, the design of which failed to take into account the final shape. As a result, dental technicians were prone to building excessive thickness into porcelain layers which were unable to resist high occlusal pressure. Nowadays, it is standard for the final shape to be taken into account in the framework design resulting in reduced chipping issues. I must mention here that CERABIEN™ ZR, which was launched at that time, showed a higher endurance ratio than others in trials and was well accepted by the market.

What we want to offer with CERABIEN™ MiLai is a similar or developed version concept of this framework design. You can reduce the risk of problems post-installation of the restoration by minimizing the porcelain thickness while maximizing the area of dental zirconia which has such strong properties that almost no chipping issue can be expected.

As a result, the micro-layering technique, which can prevent post-installation problems, should prove ground-breaking for dental technicians.

Photo: MDT Giuliano Moustakis

WHAT DID YOU DO TO MEET THESE DEMANDS?

The thinking behind the development of CERABIEN™ MiLai has been to focus on delivering thin layering that replicates the enamel structure, thus allowing technicians to achieve desired shades regardless of the depth of a layer.

HOW DID YOU MANAGE TO DECREASE THE FIRING TEMPERATURES AND WHAT IS THE EFFECT OF THIS FEATURE?

Up to now, it has generally been tricky to achieve low firing temperature while maintaining a low coefficient of thermal expansion, because they contradict each other. However, thanks to the technologies and knowledge we have cultivated since the development of Noritake Super Porcelain AAA, we could finally be breaking through this obstacle. As a result, CERABIEN™ MiLai can even be used with lithium disilicate materials, which should be baked at low temperature to avoid damaging the material.

DUE TO THE FACT THAT CERABIEN™ MILAI CAN BE APPLIED NOT ONLY TO ZIRCONIA BUT ALSO TO LITHIUM DISILICATE MATERIALS, E.MAX FOR EXAMPLE, HAVE NEW SHADES/MASSES BEEN SPECIALLY DEVELOPED THAT HAVE BEEN PERFECTLY ADAPTED FOR LITHIUM DISILICATE MATERIALS?

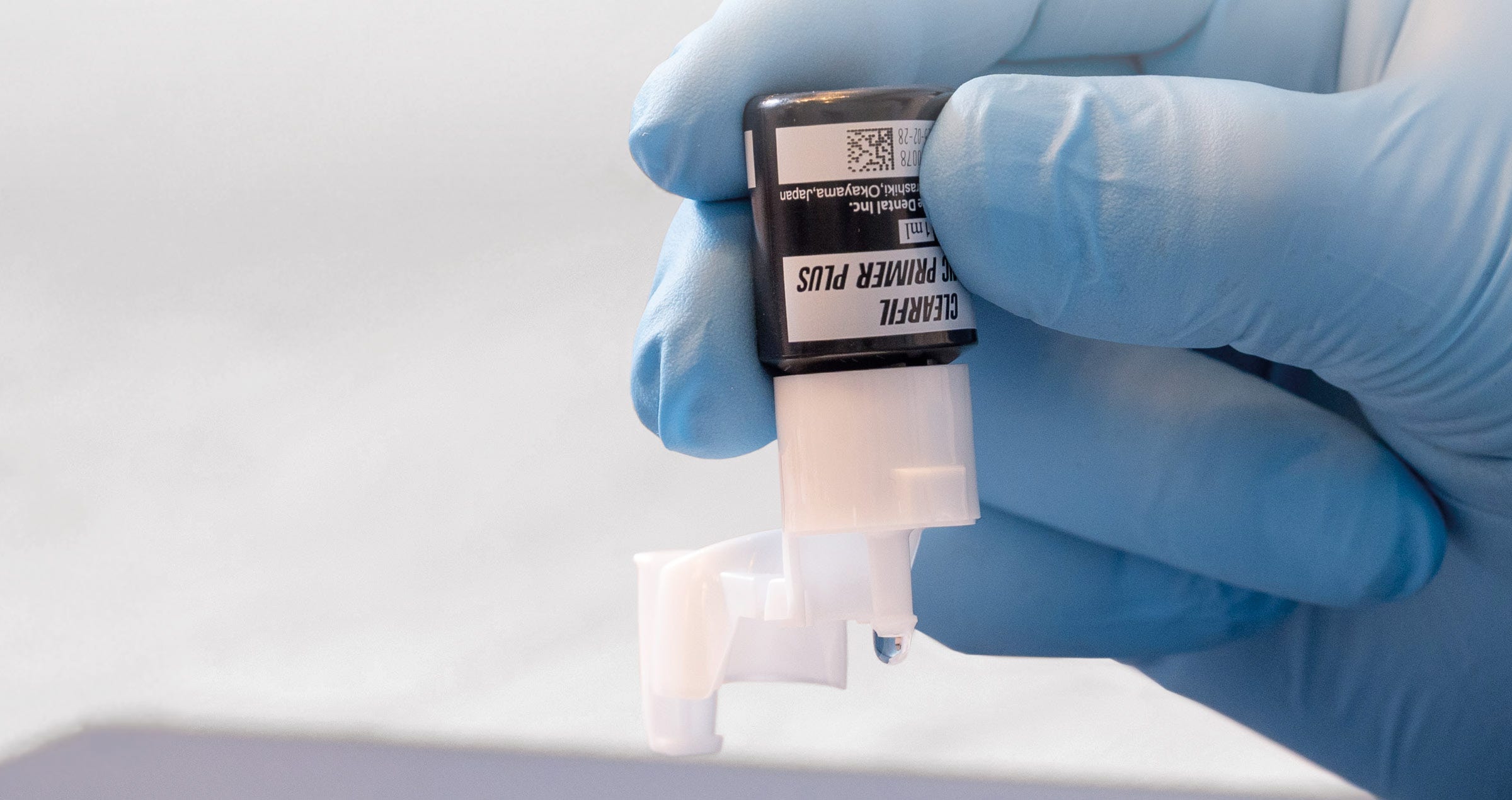

The Value Liner has primarily been developed to achieve high aesthetics from lithium disilicate materials, even lithium disilicate which has high translucency compared to zirconia materials. Also, the key for adapting for lithium disilicate is the firing temperature which I mentioned earlier. To match the colour of restoration with the tooth, the selection of framework colour is important both for lithium disilicate materials and zirconia materials. We recommend selecting one shade brighter than the target shade taking into consideration the utilization of internal stain to express the detailed character of a tooth.

CERABIEN™ MiLai can even be used with lithium disilicate materials, which should be baked at low temperature to avoid damaging the material.

WHAT DID YOU DO TO ENABLE THE IMITATION OF VIRTUALLY EVERY TOOTH SHADE WITH JUST 16 PORCELAINS AND 15 INTERNAL STAINS?

We have prepared Value Liner porcelains, which can be utilized for adjusting the value of restorations. These Value Liner porcelains and internal stains are important to adjust colour and express detailed characters. As micro-layering does not require body porcelains, since it is expected that the framework material itself – either zirconia or lithium disilicate – would express the dentine structure, adjusting the colour and value respectively with internal stains and Value Liners is essential. To reproduce the enamel structure, users can use the 16 shades of porcelains as they are, or they can mix the shades to find the desired colour. These 16 porcelains and 15 internal stains have been through trials conducted with KOLs across the world, including Europe, so we want to reassure you that even the world’s most skilled KOLs have tested and confirmed quality and effectiveness of CERABIEN™ MiLai.

Photo: MDT Giuliano Moustakis

WHAT IS THE BENEFIT OF THIS SLIM LINE-UP?

The biggest benefit of CERABIEN™ MiLai is a simple procedure. Thanks to its simplicity, not only Kuraray Noritake Dental porcelain users but also new users and beginners can achieve excellent results with this porcelain series without struggling with complicated procedures.

HOW LONG DID IT TAKE YOU TO DEVELOP CERABIEN™ MILAI (FROM THE INITIAL IDEA TO THE AVAILABLE PRODUCT)?

We initially came up with the concept in 2015 when KATANA™ Zirconia STML and UTML were launched. The development project itself was started in 2019.

We created CERABIEN™ MiLai believing that the micro-layering technique would become the standard in porcelain restorations and that CERABIEN™ MiLai would become the material of choice for dental technicians.

DID YOU COME ACROSS ANY SPECIFIC CHALLENGES DURING THE DEVELOPMENT PROCESS?

The biggest challenge we faced was the development of a material which would be compatible with lithium disilicate. We had already produced porcelains which are compatible with zirconia or metal, but up to that point we had not created porcelains for lithium disilicate before CERABIEN™ MiLai. Not only did we have to develop the material within our R&D department, but also alter the production and inspection processes in collaboration with many other departments.

THE PRODUCT NAME CERABIEN™ MILAI IS DERIVED FROM THE WORD "MIRAI", WHICH MEANS AS MUCH AS "FUTURE" IN JAPANESE. HOW MUCH FUTURE IS THERE IN THIS MATERIAL OR, TO BE MORE PRECISE, IS THIS MATERIAL A PIONEER FOR THE FUTURE PRODUCTION OF HIGHLY AESTHETIC RESTORATIONS?

We created CERABIEN™ MiLai believing that the micro-layering technique would become the standard in porcelain restorations and that CERABIEN™ MiLai would become the material of choice for dental technicians.

Building up dental porcelains is not an easy process; it takes time to acquire the knowledge and master the technique. On top of this, dental technicians have long been plagued with post-installation problems such as chipping.

Micro-layering with CERABIEN™ MiLai enables every dental technician, from newcomers through to those with many years’ experience, to create better restorations. It is our hope that dental technicians everywhere will get to experience the ease at which aesthetic restorations can be realised with CERABIEN™ MiLai, just adding one step of micro-layering.

WHAT IS YOUR VISION WITH REGARD TO FUTURE DEVELOPMENTS IN THE AREA OF PORCELAIN FOR CERAMIC LAYERING?

Personally, I think the trend will continue to shift towards easier handling while maintaining good aesthetics, as can be seen by the recent increase in popularity of the micro-layering technique.

WHAT ABOUT THE POTENTIAL OF NEW CERAMIC CAD/CAM MATERIALS AND THEIR SUITABILITY FOR MONOLITHIC USE?

We believe that monolithic use will increase further, because the perception of aesthetics is changing among patients as well as dentists and dental technicians. Before, a "natural" restoration was considered acceptable; now it can also be "cosmetically" aesthetic. Formerly, it was said that monolithic use was not suitable as it could not reproduce life-like restorations. Now, we believe it will be increasingly embraced as patients show a demand for cosmetically aesthetic restorations.

Our KATANA™ Zirconia has mechanical advantages: high strength and high translucency, and high potential in longevity. Since dental zirconia appeared in dental material market, its aesthetics have been improved remarkably. And we, at Kuraray Noritake Dental Inc., have been developing outstanding CAD/CAM materials and will continue creating innovative materials from now on too.

We are convinced that developing better products for monolithic use is crucial for releasing dentists and dental technicians from complicated procedures while at the same time giving patients a sense of safety as well as aesthetic satisfaction.

WHY SHOULD A DENTAL TECHNICIAN TEST CERABIEN™ MILAI?

We are convinced that, once dental technicians who use either zirconia materials or lithium disilicate to make restorations, experience the ease at which they can achieve aesthetically-pleasing restorations with CERABIEN™ MiLai, demand will grow. We would therefore like to encourage all dental technicians to give it a go and see the results for themselves!

IS THERE ANYTHING ELSE YOU WOULD LIKE TO ADD FOR CUSTOMERS?

Thank you so much for reading this article to the end. I am very honoured to finally launch CERABIEN™ MiLai. This product is the result of many struggles. I am firmly convinced that it is the answer for any dental technician eager to realise high levels of aesthetics in a restoration in just a simple step. I would ask them to please try out CERABIEN™ MiLai for themselves and experience what will become standard practice in the future, right now.

TOMOHIRO EMOTO

R&D Department Technical Group Manager

Japan Academy of Esthetic Dentistry Executive Member

Academic Lecture Committee Member