As co-editor-in-chief of the Journal of Adhesive Dentistry, Prof. Bart Van Meerbeek is one of the most respected authorities on the topic of dental bonding agents. Here, he discusses how they have advanced over the last three decades and what the future of adhesive dentistry might look like.

Prof. Van Meerbeek, how have bonding agents changed and advanced since you first began studying them?

I believe that the great progress dental adhesive technology has undergone in the last 30 years, and the progress in bonding agents in particular, has had a great impact on the field of dentistry and particularly on restorative dentistry, of course. Many of the current restorative dental procedures make use of adhesive materials and techniques and have advanced greatly compared with when I wrote my dissertation more than two decades ago on the topic of adhesion to dentine. Adhesion to enamel is, of course, relatively easy to achieve in comparison with adhesion to dentine, and when I first started researching this topic, I was limited to conducting clinical trials in which we were confronted with a relatively high number of restoration losses in the short term. I was lucky to have been able to witness first-hand the fast advancements dental bonding has made, having conducted research in this field now for nearly 30 years.

At a certain point, the research community started to realise that there is a smear layer in-between, which is created through cavity preparation, and that this layer interferes with bonding. If you want to achieve successful micromechanical and chemical bonding to the substrate, you first need to do something with this smear layer.

After this, we entered the era of conditioners and primers. In the past, the restorative community had been a little bit afraid of using phosphoric acid owing to its potential for pulp irritation. More and more, however, dental professionals began to use etchants with this chemical in them, as well as primers that effectively promoted bonding between the adhesive resin and dentine. While having achieved excellent bonding performance with multistep adhesives in the laboratory, as was later confirmed in clinical studies, further design and development of adhesive materials next focused on simplification and shortening of bonding procedures.

Out of this, two kinds of adhesives, making use essentially of two different bonding modes, arose: the etch-and-rinse adhesives and the self-etch, or etch-and-dry, adhesives. The newest generation of universal adhesives now enables dental practitioners to choose which of the two bonding modes to apply with one single adhesive formulation.

What advantages do bonded restorations offer over more traditional methods?

Bonded restorations are minimally invasive—the dentist doesn’t have to remove non-diseased tissue to create undercuts to keep the restoration in place, allowing for a more conservative approach. Keeping as much enamel as possible should be a goal of any restorative procedure, as it is simply the best tissue to bond to. Although bonding to dentine has always remained more challenging and has actually slowed down our adhesive endeavours for a long time, adhesively restoring teeth, involving also effective bonding to dentine, can today be achieved in a reliable, predictable and durable way.

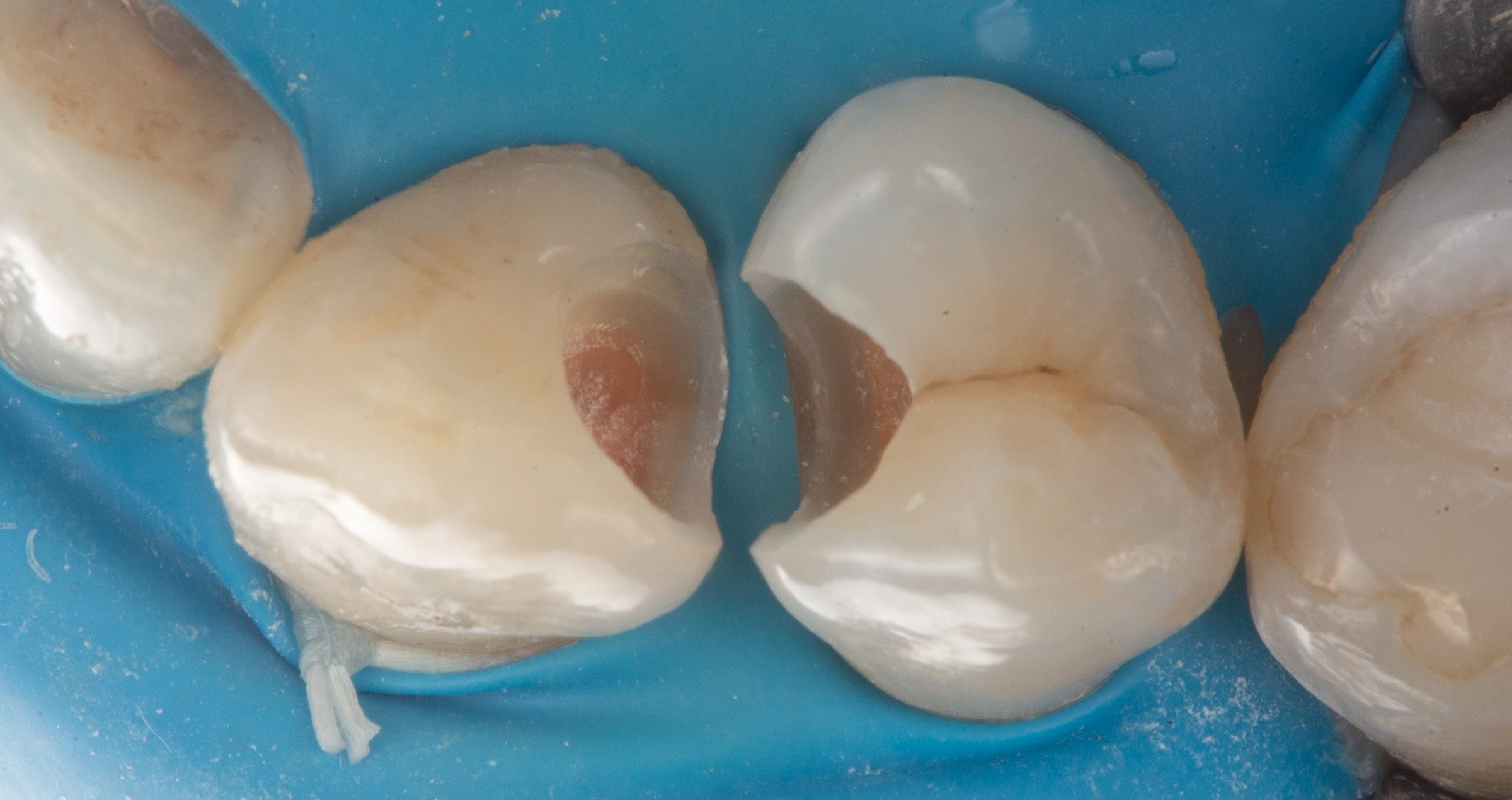

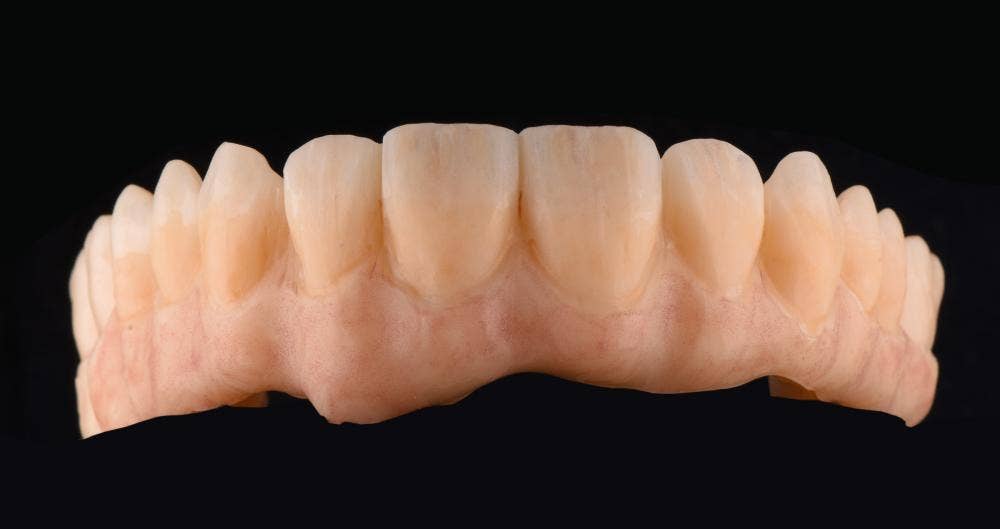

Along with highly successful implantology to replace missing teeth, lessening the need for bridges, solitary tooth restorations have substantially increased in number. Bonding promoted the additional shift from conventional tissue-invasive crowns to tissue-preserving partial tooth restorations, as modern adhesives can hold such partial restorations in place on rather flat and even non-retentive surfaces. In addition, bonding procedures allow for more natural-appearing restorations to be achieved by techniques to adhesively lute aesthetic restorations made of glass-ceramics and even the strong zirconia ceramics that no longer can be considered non-bondable.

What is your opinion regarding the current generation of universal adhesive solutions?

I think that this generation is very good, but that they are still not always as good as the more traditional gold standard two-step self-etch and three-step etch-and-rinse adhesives when it comes to their intrinsic bonding potential to dental tissue. However, I do see it as a positive that many of these universal adhesives integrate the MDP monomer, which should be considered to be one of the best functional monomers available today, though it needs to be present at a high concentration and purity level.

The MDP monomer is, generally speaking, excellent at bonding to zirconia as well. When it comes to bonding to different kinds of ceramic as well as resin-based composite restorative materials, it is always helpful to know which universal adhesives contain silane and are claimed to no longer need further treatment of the restoration. This has the advantages of lower technique sensitivity and fewer procedural steps—provided that it does, of course, work. There is current scientific evidence that the silane incorporated in today’s acidic aqueous universal adhesives is, however, insufficiently stable. Fortunately, research is underway to develop new universal adhesives that contain other silanes with higher stability in water at higher acidity.

Overall, I believe that a restoration primer that contains a high concentration of silane along with the MDP monomer is still more effective than many universal adhesives for bonding to restorative materials, since these universal adhesives can contain many other ingredients that create a kind of competition within the material to reach and interact with the substrate surface, leading to lesser bonds.

Another shortcoming of universal adhesives is their thin film thickness and relatively high hydrophilicity, promoting water uptake and hence making them sensitive to hydrolytic degradation. In this light, it’s important to note that, when a viscous and hydrophobic flowable composite is applied on top of a universal adhesive, it can make up for this somewhat and allow for durable bonding to take place.

Is the MDP monomer crucial to the ultimate success of universal adhesives? Are there other factors that can influence this?

Well, it’s very clear that the MDP monomer is one of the most effective monomers available, given its primary chemical binding potential to hydroxyapatite. However, there are significant differences in the MDP monomer purity and concentration levels between these products, factors that are affected by whether or not the monomer is synthesised by the company itself or whether this process is outsourced. Essentially, a universal adhesive that contains a high concentration of very pure MDP monomer should perform the best.

Are there any specific advantages that a self-etch adhesive possesses?

The biggest advantage is that it doesn’t remove all hydroxyapatite and minerals present in dentine and so keeps the weaker dentinal collagen protected. Phosphoric-acid etching results in relatively deep and complete demineralisation with collagen exposure, making the bond more prone to degradation. Partially maintaining minerals around collagen using a mild self-etch adhesive additionally allows for strong ionic bond formation to take place when the adhesive in particular contains the functional monomer MDP. In addition, one should be aware that, while chemical binding doesn’t necessarily lead to higher bond strength, it can create better long-term bond durability.

What do you see as the next step in adhesive dentistry?

One possibility is to reduce the number of steps in the adhesion process with the final goal of having self-adhering restorative materials. There have been developments in this direction, including studies and commercial products, though the products haven’t always proved to be very effective and their bond durability is unclear. Now, however, there are newer materials coming to market with claims that they can be used with no pretreatment. Their clinical effectiveness, nevertheless, still needs to be proved and guaranteed before such self-adhering restorative materials could be used as true amalgam alternatives in routine dental practice.

Another possibility, and current R & D hype, is the development of bioactive adhesives. Many dental researchers and many companies want adhesives not only to deliver good bonding performance but also to have certain therapeutic benefits. What exactly a bioactive adhesive is depends on who you’re talking to. Some researchers believe that they should have antibacterial qualities, whereas others state that remineralisation of dentine and pulpal cell interaction are needed to qualify for the term “bioactive”. We certainly need to investigate whether we can give these materials these additional properties, but on one condition: that the adhesive material does not lose any of its original bonding abilities. That, in my opinion, is the biggest challenge for the future of adhesive dentistry.