It is probably the best-known component of a dental product Kuraray Noritake Dental Inc. (Kuraray Noritake Dental) has ever developed: 10-Methacryloyloxydecyl Dihydrogen Phosphate, in short, the MDP monomer. Invented more than 40 years ago – the first product containing it was introduced in 1983 – MDP is still the leading functional monomer used to establish a long-term, durable and stable bond to hydroxyapatite in tooth structure and to metal oxides in restorative materials (oxide ceramics and metal alloys).

Nowadays, it is found in every dental adhesive and every component of a resin cement system with adhesive properties from Kuraray Noritake Dental. These include:

In addition, MDP has become an integral part of most universal adhesives and many adhesive cementation systems of other manufacturers as well. However, not all MDP is alike …

MDP: Chemical structure and mechanism of adhesion

The MDP monomer consists of three essential parts: A polymerizable group, a hydrophobic group and a hydrophilic group. The co-polymerizable methacrylate group has a terminal double bond enabling polymerisation. The large hydrophobic alkylene group – also referred to as the spacer – has the task to maintain a delicate balance between hydrophobic and hydrophilic properties of the monomer and offers great resistance to degradation. Finally, the hydrophilic phosphate group is responsible for acidic demineralisation, for chemical bonding with calcium in hydroxyapatite and for bonding with zirconia1 (as well as with metal).

Bonding performance

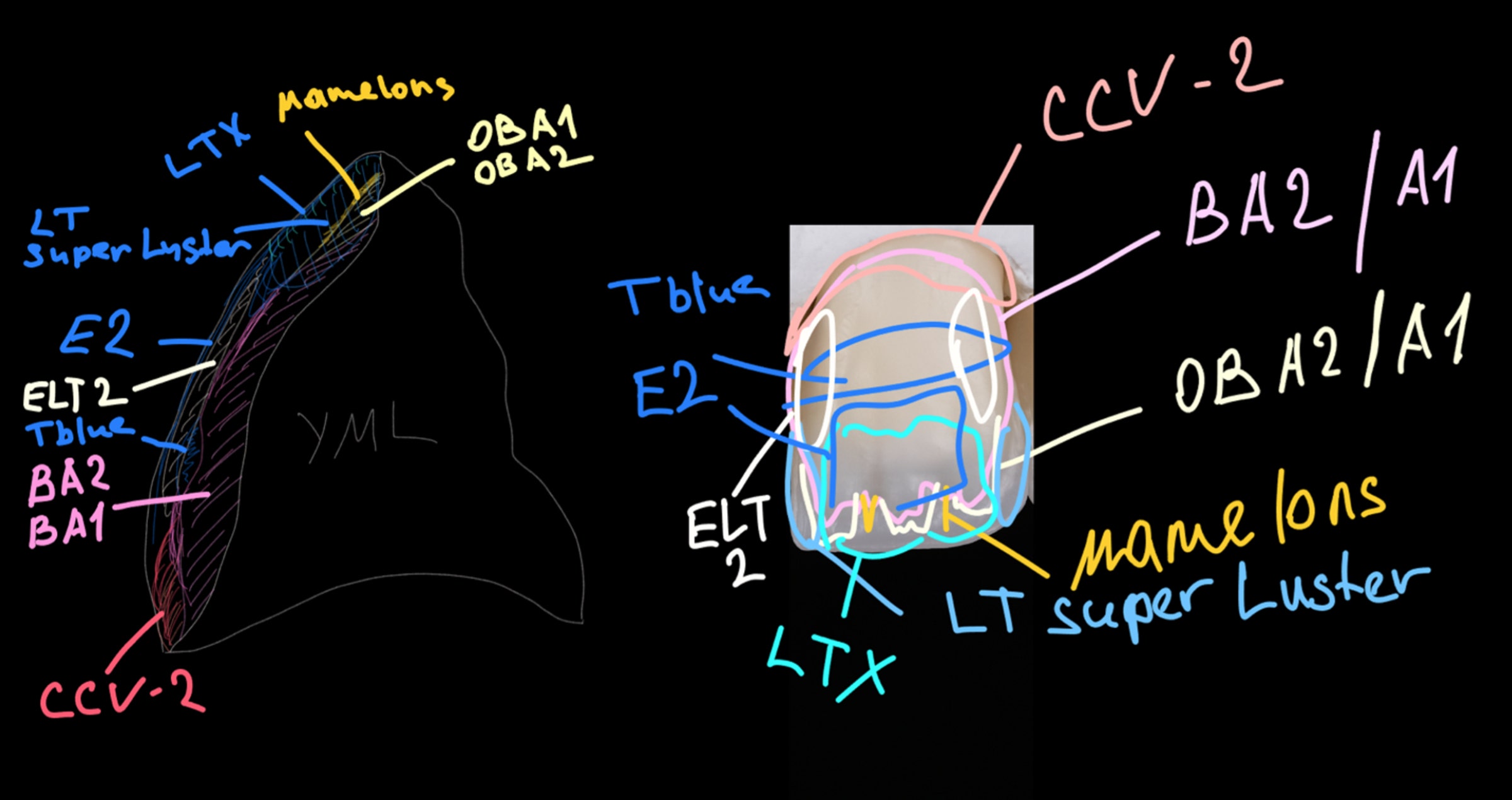

Lots of in-vitro studies have been carried out to investigate the bonding behaviour of 10-MDP in the context of direct and indirect restorative procedures. No matter whether a cavity is to be filled with resin composite or an indirect restoration is to be placed, a strong and long-lasting bond to tooth structure needs to be established.Chemical structure of adhesive monomer 10-Methacryloyloxydecyl Dihydrogen Phosphate (MDP).

The critical substrate in this context is dentin, while bonding to enamel is found to be less challenging. That is why it is so important that (self-etch) adhesives containing 10-MDP show an extraordinarily high bond strength to tooth structure, particularly to dentin2. In fact, 10-MDP also provides for a high bond stability over time by establishing an acid-base resistant zone on the adhesive interface3. This means that a great long-term performance may be expected. Fortunately, a great clinical long-term performance of products containing the MDP monomer has already been confirmed: A group from the University of Leuven (Belgium) has presented excellent results of a thirteen-year clinical trial involving the use of CLEARFIL™ SE Bond in 20154.

When bonding to indirect restorations made of zirconia, the surface area of the ceramic should be increased by sandblasting5. Pre-treated in the recommended way, the bond strength to zirconia tends to be particularly high when MDP-based resin cement systems are used6. It is thus widely recommended by experts in the field of adhesive dentistry to employ MDP-containing primers or resin cements for the placement of zirconia-based restorations, especially those with a non- or less retentive preparation. The fact that products containing 10-MDP work well in this context has been confirmed in different clinical studies with observation periods of up to 10 years7,8. The products used in these studies were PANAVIA™ 21, PANAVIA™ F2.0 and the latest version of the multi-component cementation system from Kuraray Noritake Dental, PANAVIA™ V5, which performed best.

Not all MDP is alike

Ever since the basic patent for MDP has expired, other manufacturers of dental adhesives and adhesive resin cements have started integrating the functional monomers in their own products. However, it has been revealed that there are differences in the purity of the MDP monomers synthesized and used, and that these differences have an impact on the long-term bonding performance of the products containing the MDP9. According to in-vitro test results, the Original MDP Monomer synthesized by Kuraray Noritake Dental stands out due to an unmatched level of purity. This purity has a positive effect on the microstructure and thickness of the hybrid layer formed on dentin, the intensity of nano-layering and the bond strength measured immediately as well as after artificial aging9.

Conclusion

The data summarized above reveals that after 40 years in clinical service, the Original MDP Monomer from Kuraray Noritake Dental is still a class of its own. It has everything needed to establish a strong and long-lasting bond to tooth structure, resin composite and metal oxides, and is therefore a valuable component in virtually every adhesive system. In order to provide for a high bond quality, however, it may be best to use an MDP monomer with a confirmed high purity – the Original MDP Monomer.

References

1. Nagaoka N, Yoshihara K, Feitosa VP, Tamada Y, Irie M, Yoshida Y, Van Meerbeek B, Hayakawa S. Chemical interaction mechanism of 10-MDP with zirconia. Sci Rep. 2017 Mar 30;7:45563.

2. Fehrenbach J, Isolan CP, Münchow EA. Is the presence of 10-MDP associated to higher bonding performance for self-etching adhesive systems? A meta-analysis of in vitro studies. Dent Mater. 2021 Oct;37(10):1463-1485.

3. Carrilho E, Cardoso M, Marques Ferreira M, Marto CM, Paula A, Coelho AS. 10-MDP Based Dental Adhesives: Adhesive Interface Characterization and Adhesive Stability-A Systematic Review.

4. Peumans M, De Munck J, Van Landuyt K, Van Meerbeek B. Thirteen-year randomized controlled clinical trial of a two-step self-etch adhesive in non-carious cervical lesions. Dent Mater. 2015 Mar;31(3):308-14.

5. Kern M, Barloi A, Yang B. Surface conditioning influences zirconia ceramic bonding. J Dent Res. 2009; 88: 817–822.

6. Özcan M, Bernasconi M. Adhesion to zirconia used for dental restorations: a systematic review and meta-analysis. J Adhes Dent. 2015 Feb;17(1):7-26.

7. Kern M, Passia N, Sasse M, Yazigi C. Ten-year outcome of zirconia ceramic cantilever resin-bonded fixed dental prostheses and the influence of the reasons for missing incisors. J Dent. 2017 Oct;65:51-55.

8. Bilir H, Yuzbasioglu E, Sayar G, Kilinc DD, Bag HGG, Özcan M. CAD/CAM single-retainer monolithic zirconia ceramic resin-bonded fixed partial dentures bonded with two different resin cements: Up to 40 months clinical results of a randomized-controlled pilot study. J Esthet Restor Dent. 2022 Oct;34(7):1122-1131.

9. Yoshihara K. et al. Functional monomer impurity affects adhesive performance. Dent Mater. 2015 Dec;31(12):1493–1501.