Some companies mainly make use of basic technologies developed by others to improve their products and introduce new ones, while other companies conduct fundamental research and basic technology development inhouse. Is this difference relevant for someone who uses the resulting products in the dental practice or laboratory on a daily basis? It is – as companies developing everything from scratch usually have a deeper understanding of the products and their production procedures, which makes it easier for them to modify specific features, solve existing problems and respond to market needs. This article describes the impact of two basic technologies developed by Kuraray Noritake Dental Inc. on the production of zirconia-based indirect restorations.

All-ceramic evolution

A milled monolithic or only minimally reduced core made of high-strength ceramics plus a micro-layer of porcelain: this is today’s success formula for the production highly aesthetic indirect restorations. The approach is by far less complex and time-consuming than traditional production and layering procedures, while its outcomes can be quite impressive. Concerning aesthetics and function, however, it is essential that the right types of material are selected and combined.

The core: Multi-Layered Zirconia Technology

When the first opaque zirconia framework materials conquered the dental market, leading manufacturers never grew tired of stressing that not all zirconia is alike. Instead, huge quality differences do exist depending on the raw materials selected as well as the processing techniques and equipment used for blank production. With an increasing aesthetic potential of the core materials and a decreasing thickness of the veneering porcelain on top, this fact becomes more relevant than ever.

When Kuraray Noritake Dental Inc. identified the need for more aesthetic zirconia core materials with a higher translucency and a tooth-like colour structure, it decided to develop a completely new type of dental zirconia. It started establishing a sophisticated raw material production, blank pressing and pre-sintering process inhouse. This was the basis for the development of the dental industry’s first polychromatic blank with a seamless colour structure and precise shade match with tabs of the VITA™ classical shade guide. In order to identify the best ingredients and procedures, the R&D team experimented with different raw materials, formulations and grain sizes, developed ways to optimize the purity of the ingredients and focused on perfectioning the homogeneity and density of the blanks and – of course – the integrity of the different layers. Currently, three different products based on this original Multi-Layered Zirconia Technology are available for dental laboratories: KATANA™ Zirconia UTML, KATANA™ Zirconia STML and KATANA™ Zirconia HTML PLUS. They offer different levels of translucency and flexural strength.

KATANA™ Zirconia Multi-Layered disc with four-layer colour structure.

Three different products with four-layer colour structure, differing in terms of translucency and flexural strength.

In June of 2021, Kuraray Noritake Dental Inc. introduced a new, next level Multi-Layered Zirconia disc – KATANA™ Zirconia YML. This time, the company responded to the marked need for a universal zirconia with a high aesthetic potential. The blanks offer colour, translucency and flexural strength gradation – with the highest translucency in the enamel and the highest flexural strength in the lowest body layer.

KATANA™ Zirconia YML: Multi-Layered Zirconia disc with colour, translucency and flexural strength gradation.

All Multi-Layered Zirconia discs and technology incorporated in them support the production of lifelike restorations with reduced hand work. No matter whether the user prefers to work with materials offering a uniform strength and selects them depending on the indication or with the universal solution: the finishing effort is reduced considerably due to the optimized translucency and natural colour gradation of the core materials. At the same time, the quality of the produced restorations is high thanks to regular margins, smooth surfaces and a precise fit (as a result of the homogeneous, high-density structure with low porosity and a high level of purity).

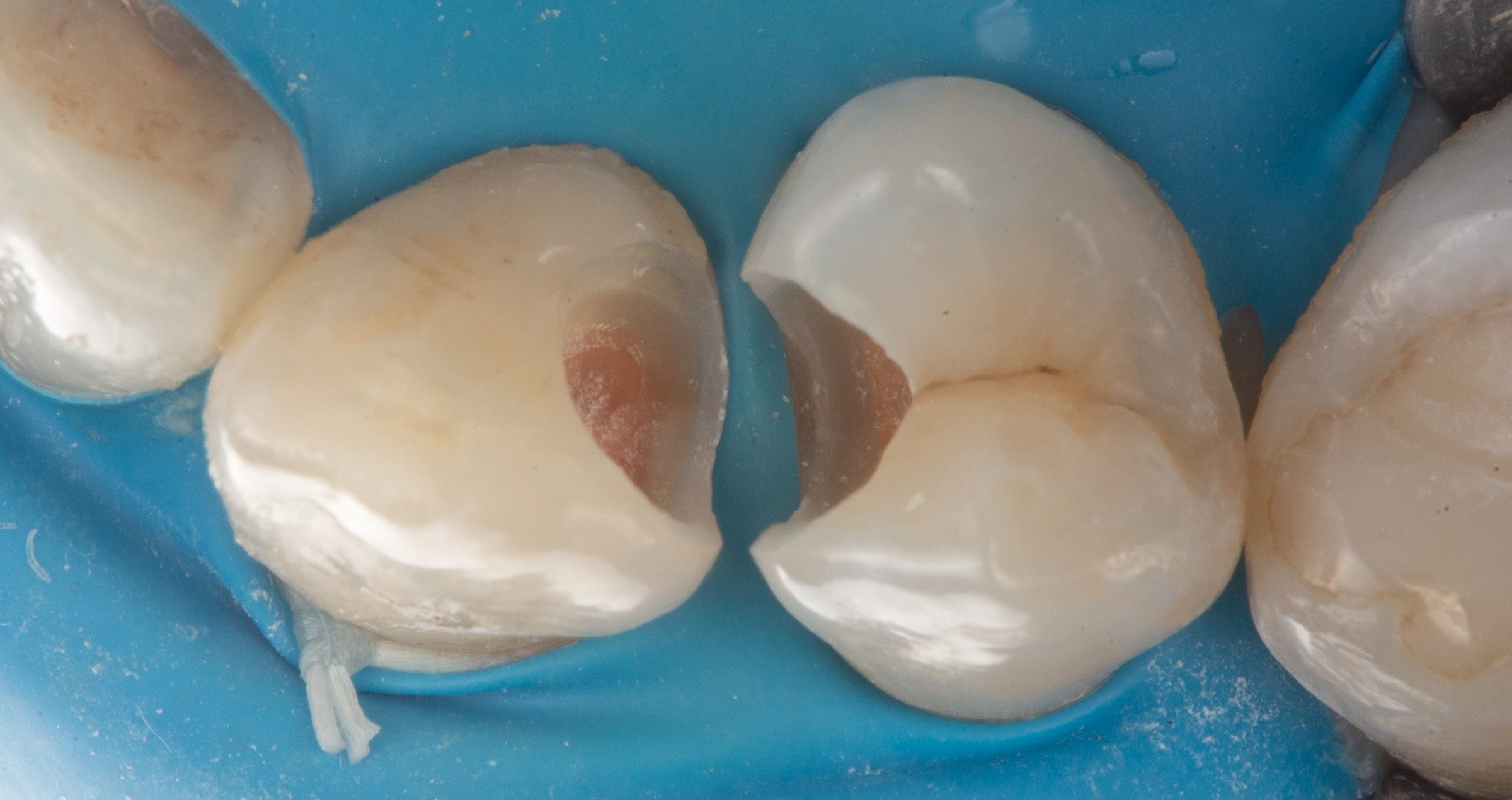

Extremely regular margins of a KATANA™ Zirconia crown after milling, which is also a result of the favourable material structure.

The micro-layer: Synthetic Feldspathic Porcelain Technology

Differences are not only found in zirconia, but also in the performance of veneering porcelains. They typically consist of feldspathic porcelain, and most of them are based on natural feldspar. Depending on where this feldspar is mined, it may have slightly different properties. That is why manufacturers of this natural feldspar-based veneering porcelains need to adjust their formulations from time to time, and handling and aesthetic properties might be somewhat different with every new system purchased. In the 1980s, these variations in the composition of natural feldspar led to unpredictable material properties causing difficulties in reproducing the natural tooth colour and even porcelain fractures and cracks appearing after firing of porcelain-fused-to-metal (PFM) restorations. A limited colour stability was also an issue.

For Noritake, one of the parent companies of Kuraray Noritake Dental Inc., these issues were reason enough to start developing a different kind of porcelain. After analysing the issues and weighing the possibilities, a completely new Synthetic Feldspathic Porcelain Technology was developed. It provides for stable coefficients of thermal expansion, particle distribution and colour, as it is no longer dependent on natural sources of feldspar.

Originally, this technology was used in Super Porcelain AAA (EX-3) introduced in 1987, a veneering porcelain for metal frameworks. However, the technology also formed the basis for the development of CERABIEN™ ZR Porcelain and CERABIEN™ ZR FC Paste Stain for porcelain layering on zirconia. This line-up of internal stains and porcelains was specifically developed for micro-layering on zirconia.

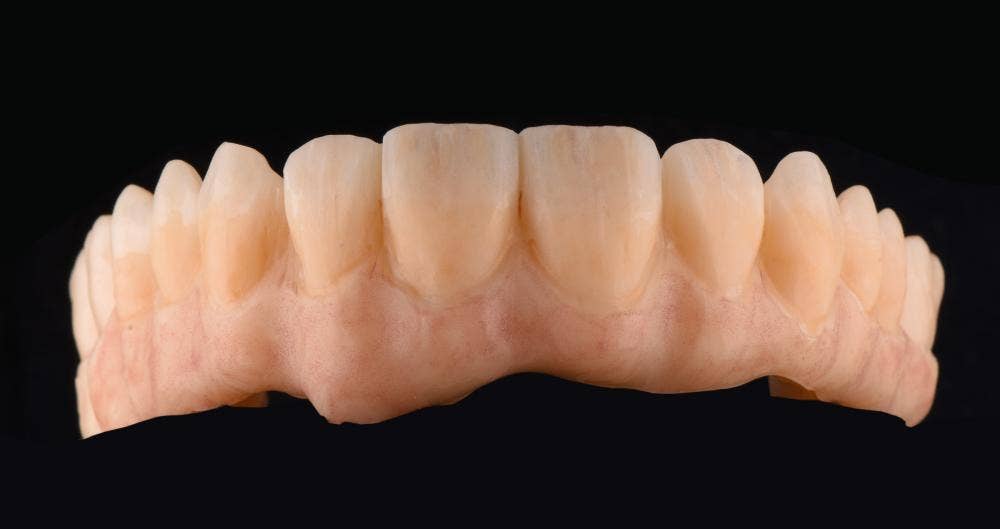

All products have one thing in common: as they are based on synthetic feldspathic porcelain, they offer consistent mechanical and handling properties and predictable shade effects. The material structure and particle distribution resemble those of natural teeth, supporting lifelike outcomes. A reduced effort is achieved with the liquid ceramic system CERABIEN™ ZR FC Paste Stain used on a monolithic restoration or one with a minimal cut-back (0.1 mm).

Different micro-layering approaches with CERABIEN™ ZR FC Paste Stain…

…and CERABIEN™ ZR Internal Stain plus Luster Porcelain leading to highly aesthetic outcomes.

Connecting elements: Touch-Cure and Monomer Technology

When needing to cement the finished prosthetic restorations on implant abutments or frameworks, it is essential to select a cementation system that is able to fulfil high aesthetic and functional demands. The PANAVIA™ family of resin cements from Kuraray Noritake Dental Inc. contains many different technologies that provide for a high bond strength to various substrates and a tight marginal seal. The key technology incorporated in any cement is the Original MDP Monomer invented by Kuraray in 1981. It is capable of establishing a particularly strong and long-lasting bond to enamel, dentin, metal and zirconia. The self-adhesive resin cement PANAVIA™ SA Cement Universal also contains the LCSi Monomer, a Long Carbon-chain Silane coupling agent. This monomer forms a strong chemical bond with resin composite, porcelain and silica-type ceramics (like lithium disilicate), so that the need for a separate silane component (a primer or adhesive) is eliminated when bonding these types of prosthetic restorations. PANAVIA™ V5, the strongest cement in PANAVIA™ line, is equipped with Touch-Cure Technology. It seals the interface between the tooth and the restoration to prevent micro-leakage, provides for a high polymerisation ratio even when dark-curing and hence delivers a strong bond in virtually every situation.

Conclusion

KATANA™ and CERABIEN™ are excellent partners that allow for a simplified approach to lifelike restorations. The high level of quality and reliable performance offered by the solutions are due to proprietary technologies and streamlined inhouse production procedures that really make a difference. And whenever needing to cement prosthetic restorations on implant abutments or frameworks, PANAVIA™ resin cement systems based on proprietary monomer and curing technology are a perfect choice.