Interview with Andreas Chatzimpatzakis

Fewer bakes, fewer ceramic powders - there is clearly a trend toward simplification in the production of zirconia-based prosthetic work. This is also true for implant-based restorations, which often involve gum parts. DT Andreas Chatzimpatzakis, international trainer for Kuraray Noritake Dental Inc., and the owner of ACH Dental Laboratory in Athens, Greece, shares his approach to high aesthetics in implant prosthodontics in the following conversation.

You are a user of the CERABIEN™ ZR portfolio from the outset. When did you test the products for the first time and why?

Well, it was many years ago when I finished my very first zirconia-based restoration. The reason to test CERABIEN™ ZR was that when I asked the dental technician who had milled the framework which porcelain system to use. He suggested to use CERABIEN™ ZR, which I did. I was immediately impressed by the system and by the outcome I was able to achieve on the first attempt.

Did you ever test any other porcelain systems for ceramic layering?

Yes. Before I becoming an international trainer for Kuraray Noritake Dental Inc., I had the opportunity to test many other porcelain systems for layering on zirconia. Based on this experience, I can say that CERABIEN™ ZR is unique and the best system I have ever used. The reason is that its translucency and chroma are extremely close to natural teeth. In addition, due to a controlled firing shrinkage, a One-Bake Technique may be employed even in long-span restorations.

Your hands-on demonstration at the Kuraray Noritake Dental booth during the IDS 2023 in Cologne focused on White and Pink Aesthetics achieved with CERABIEN™ ZR. Is there a specific concept you use?

Nowadays, everyone producing dental restorations – no matter whether based on natural teeth or on implants – is confronted with increasing aesthetic demands of patients and dental practitioners. The high demands are developed because life-like restorations and cosmetic dental treatment outcomes are presented everywhere in the web and on social media. The showcased quality of outcomes is simply expected, even if the financial budget is limited. To be able to fulfil these demands in the field of implant-based prosthodontics, I have developed an approach that allows me to achieve high aesthetics with little effort. My concept is based on using not too many ceramic powders. For extra chroma and special characterization, I rely on the power of the internal live stain technique, first introduced by Hitoshi Aoshima-sensei.

Please summarize the most important details of your presentation.

The first important detail is the design and characterization of the framework. Before sintering, I apply Esthetic Colorant for KATANA™ Zirconia. After the sintering process, shade base stain and internal stains are mixed and applied. In this way, I create a nice canvas that helps me to achieve a life-like result with only a few selected ceramic powders. In most cases, three to five powders are enough to produce a great result. Among the powders used most frequently are Opacious Body, Body, LTX, Mamelon and CCV. After the first bake and a little grinding, I make use of internal stains again. They offer support in the controlling of the chroma and the integration of special characteristics. When this step is completed, the final build-up is done with one or two ceramic powders, most of the times LT1 and Enamel or LT0. Pink aesthetics are usually created with Tissue 1, 3 and 5. For the free gingiva, LT Coral is my go-to solution. The major goal is always to obtain maximum quality in a minimum of time. To achieve this, a good knowledge of the materials and of course practicing – on both, porcelain build-up and morphology – are strictly required.

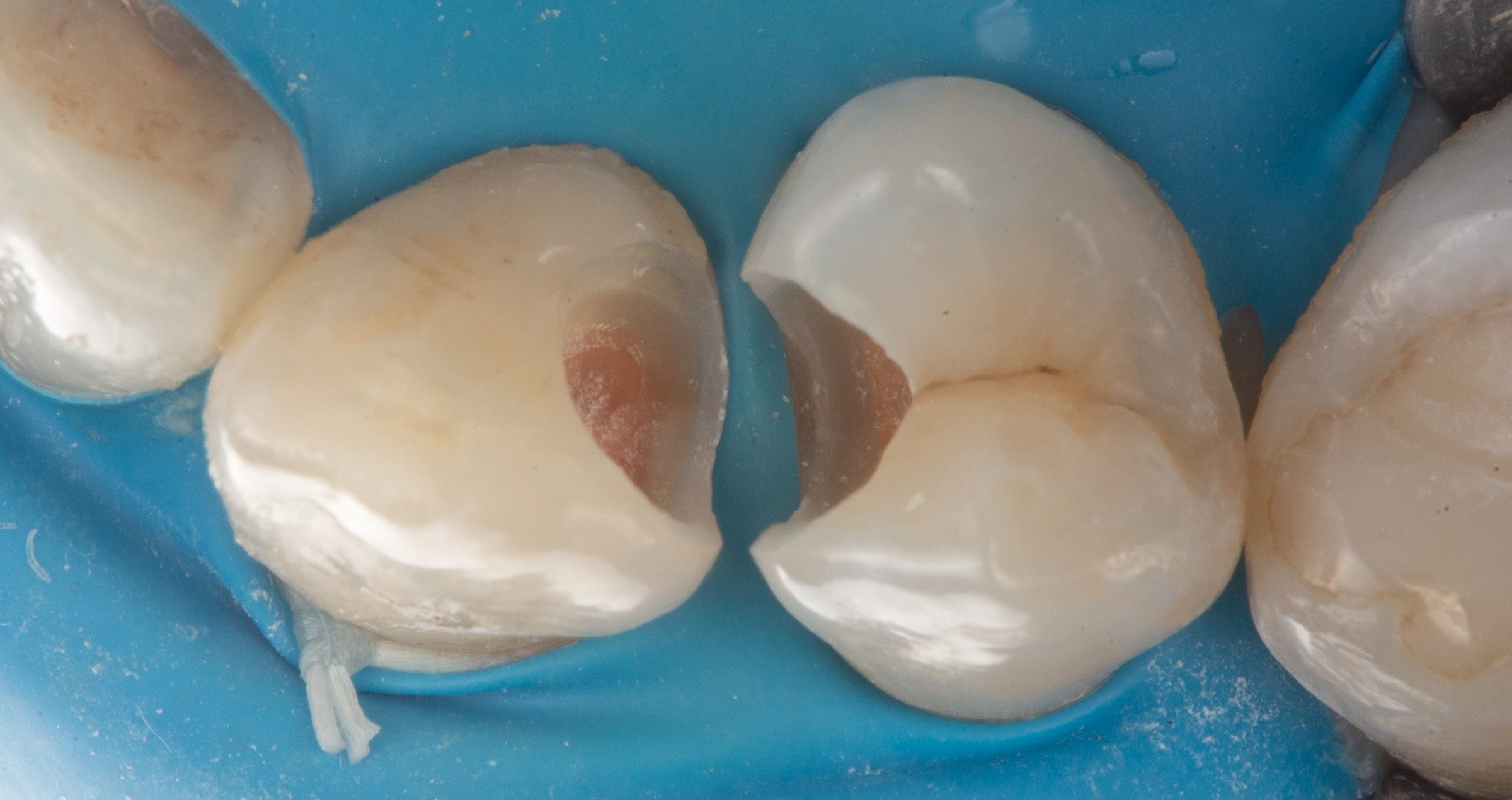

Fig. 1. Complex implant-based restoration: Framework design.

Fig. 2. Esthetic Colorant …

Fig. 3. … applied prior to the final sintering procedure.

Fig. 4. Appearance after sintering.

Fig. 5. Final outcome.

Are there any concrete tips and tricks you would like to share?

For the characterization of the framework, I mix the internal stains with shade base stain powders; mostly with SS Fluoro. For the first bake, especially when the restoration is large and the amount of ceramic to be applied huge, I reduce the heating rate up to 38 degrees per minute. I also increase the drying process up to 17 or even 20 minutes depending to the restoration. Experience shows that these measures optimize the aesthetic outcomes.

You often mention that it is extraordinarily important to understand the morphology of natural teeth to be able to produce beautiful restorations. Why is this the case?

A successful prosthetic restoration needs to offer proper function and aesthetics. Function means a precise fit, perfect contact points and occlusion, a proper emergence profile and interproximal embrasures for self-cleaning etc. All this is described by the term morphology. Aesthetics, on the other hand, is guided by shape and colour. The effort required to establish a proper morphology is much higher (about 70 percent of the total work) than the effort involved in obtaining the right translucency, opalescence and chroma.

What instruments do you use to imitate the morphology of natural teeth and how do you do it?

I usually make use of the Optimum™ Spring Ceramic Brush Size 8 (MPF Brush Co.), stones and diamond burs for detailed grinding and carving after the final bake. I studied morphology at the Osaka Ceramic Training Centre in Japan with Shigeo Kataoka-sensei. According to him, a key factor in creating a perfect macro and micro morphology lies in the shadows. To be able to take into account the interference of light and shadow during grinding, a light source is placed on one side of the restoration.

How many bakes do you need to produce highly aesthetic restorations?

It depends on the case, although in many situations, I nowadays opt for some kind of micro-layering. Lately, I have used micro-layering a lot with internal stain directly on the zirconia framework. In other cases, I do a quick first bake, then the internal staining, a final bake and glazing. For small or single-unit restorations in the posterior region, a One-Bake Technique is often sufficient. Even a Zero-Bake approach using Esthetic Colorant on a monolithic zirconia restoration may be appropriate here, and it is very convenient. If there is a restoration with high aesthetic demands – these are typically single anterior restorations – the technique I select depends on the shade. In some cases, using only the internal stain technique is enough to reach a high aesthetic level, while in other cases, additional steps need to be taken. To my mind, there is no single technique that fits all cases. As mentioned before, I try to achieve high aesthetics in a minimum of time.

Fig. 6. Clinical example of achieving high aesthetics in a minimum of time: Before …

Fig. 7. … and after crown placement.

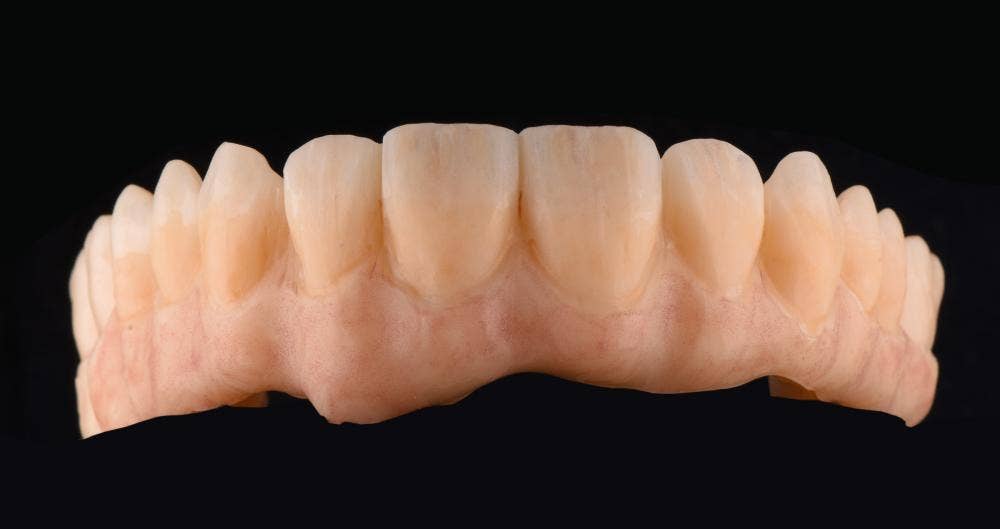

Fig. 8. High aesthetics …

Fig. 9. … achieved in a minimum of time.

Did your approach change due to the availability of high-translucency zirconia materials with colour (and flexural strength) gradation?

Well, yes! My overall approach changed more to micro-layering. Several years ago, we needed to consider how to mask the framework and how to achieve translucency in areas with limited space. The problem was solved for single-unit and small anterior bridge restorations with the availability of KATANA™ Zirconia UTML and STML. With the introduction of KATANA™ Zirconia YML, a high-translucency material became available for long-span or implant-based restorations as well. We have strength and translucency all in one disc. In most of my cases, the framework material replaces the dentin with regard to morphology and shade. Hence, I need to focus on adding the enamel by applying the transparent and translucent powders. The powders of the internal stain technique are used to characterize the framework, and with a micro-layer of porcelain, the goal of creating an aesthetic restoration in the minimum of time is achieved. This is exactly why I am sure that micro-layering is the future.

What drives you to share your knowledge with others?

My passion! I love my work! And I love to see technicians become better and better. Dental technology is an exciting journey, a journey that begins when the first impression arrives in the dental laboratory, and it ends when the final restoration is cemented into the patient’s mouth. And this journey is so exciting because we change lives. We change people’s personalities, we give them back their smile, we give them back their self-respect. Consider that every day, every single moment working on our bench trying to imitate nature… there is nothing more exciting than that!!!

My approach as an instructor is to lead dental technicians to master the art of observing natural teeth. This is the way every individual will understand morphology and shade. You need no special talent to be a very good dental technician. You need to observe! Your eyes see, your mind understands, and your hands will follow.