Steve Meeze definitely has it: a passion for dentistry. Yet, there was a time when he was unhappy in his job as a dental practitioner. Fundamental changes were necessary to lay the foundations for finding personal fulfillment in his work. We spoke to him about his motivation to do things differently and about the path he has chosen and is following down to the present day.

Many students of dentistry would like to run their own dental office one day. For you, this dream came true, but you ultimately decided to take a different path. Why did this change seem necessary?

After graduation in 1983, running my own dental office seemed to be a great plan: I wanted to be independent, grow my patient base, and become successful, which went very smoothly in the beginning. This economic success, however, did not protect me against starting to feel unhappy and burned-out after several years. Once I began to take my negative emotions seriously and to search for the underlying causes, I realized that is was not merely the workload that troubled me. The truth was that I was missing a sense of purpose in many of my daily tasks. This seemed to be the reason for my lack of energy and motivation to proceed with what I had started. Luckily, I was able to find my personal “why” after some time.

Where did you find your own fulfillment or sense of purpose?

I ultimately found it in the field of conservative dentistry. The reason is that direct restorative treatments with composite allow me to do amazing things in a non-invasive or minimally invasive way. Doing no harm and always being able to go back simply feels good, and my patients are incredibly grateful for what I do. Their gratitude is my reward. This is why I decided to dedicate myself exclusively to treating patients with composite.

How do you do this?

In 2009, I sold my own dental office and started working in different practices in Flanders. In this process, I established some highly valuable partnerships with colleagues, who appreciate my skills and refer their patients to me mainly in the course of interdisciplinary treatment. These orthodontists or surgeons need someone who puts the finishing touches to their work. And this is exactly what I do: I create a beautiful smile at the end of an often complex treatment. Other patients approach me on their own accord with fractured or misshaped teeth and the desire for esthetic improvement. In any case, I listen to them carefully before I start planning. Knowing what is on their minds, I can treat them with confidence. The most precious moment for me is when I hand over the mirror and let them evaluate my work. Their positive reaction, the glint in their eyes is what motivates me every day.

Is there a specific technique you use in your daily work?

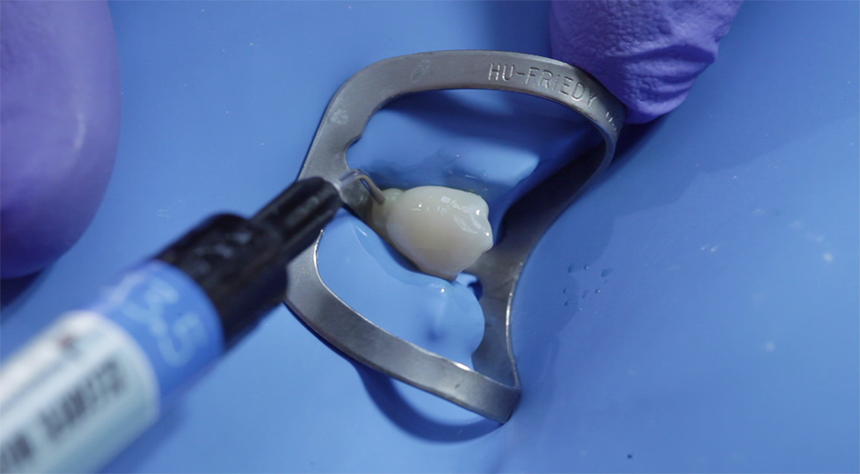

Yes, I use the Light Facing Concept I developed to solve esthetic issues in the anterior region. This technique focuses of creating a harmony without the need to sacrifice large amounts of healthy tooth structure. With this concept, a fractured anterior tooth, for example, is restored in three steps: Initially, a single dentin shade of composite of the same color as the fractured tooth is used to create the desired tooth shape and make the fracture line disappear. In this step, shade selection is independent of the final color I would like to reach. Subsequently, I correct the color with an opaque material and try to match the shade of the adjacent teeth as exactly as possible. If necessary, I create mamelons and other individual characteristics in this layer. The final step is carried out on all anterior teeth whenever the appearance of the treated tooth differs from the others: A light facing – i.e. a very thin layer of more or less translucent composite – is added to mask the differences. In cases with minimal shade differences, a composite with a high translucency is used, while a more opaque material is preferable whenever the differences are more apparent.

What is your preferred material for the Light Facing Concept?

My personal experience shows that the best results are obtained with CLEARFIL MAJESTY ES-2 Premium composite from Kuraray Noritake. It simply offers the best mimetic (chameleon) effect of all composite materials I have tested so far, and I have tested many of them. The material tends to blend in with the surrounding tooth structure, and only four shade combinations are usually sufficient to cover the whole range of my patients’ tooth shades. I love this virtually magical effect!

What is your personal conclusion?

When I made the decision to start doing what really makes me happy, I could not be sure that I had chosen the right path. Retrospectively, I know that giving up my present career and taking steps towards personal fulfillment has been exactly the right thing to do. I love the fact that I can satisfy my patients’ desires without sacrificing healthy tissue, and my Light Facing Concept implemented with MAJESTY ES-2 make it easy for me to obtain the results they have been dreaming of.

CASE EXAMPLES

Fig. 1 : Case example: Color change with composite – initial clinical situation.

Fig. 2.: Case example: Color change with composite – treatment outcome.

Fig. 3: Case example: Shape correction with composite – initial clinical situation.

Fig. 4: Case example: Shape correction with composite – immediate treatment outcome.